|

|

1

|

|

2

|

In the Select Physics tree, select AC/DC>Electromagnetics and Mechanics>Rotating Machinery, Magnetic (rmm).

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Part Libraries window, select AC/DC Module>Rotating Machinery 2D>Rotors>Internal>surface_mounted_magnet_internal_rotor_2d in the tree.

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 click Internal Rotor – Surface Mounted Magnets 1 (pi1).

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

In the Part Libraries window, select AC/DC Module>Rotating Machinery 2D>Stators>External>slotted_external_stator_2d in the tree.

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 click External Stator – Slotted 1 (pi2).

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Add dialog box, in the Selections to add list, choose Rotor air (Internal Rotor – Surface Mounted Magnets 1) and Stator air (External Stator – Slotted 1).

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Add dialog box, in the Selections to add list, choose Rotor iron (Internal Rotor – Surface Mounted Magnets 1) and Stator iron (External Stator – Slotted 1).

|

|

5

|

|

1

|

|

2

|

|

3

|

In the tree, select Built-in>Air.

|

|

4

|

|

5

|

|

6

|

|

7

|

In the tree, select AC/DC>Copper.

|

|

8

|

|

9

|

In the tree, select AC/DC>Hard Magnetic Materials>Sintered NdFeB Grades (Chinese Standard)>N54 (Sintered NdFeB).

|

|

10

|

|

11

|

In the tree, select Built-in>Iron.

|

|

12

|

|

13

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Materials click Soft Iron (Without Losses) (mat2).

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Locate the Domain Selection section. From the Selection list, choose Odd magnets (Internal Rotor – Surface Mounted Magnets 1).

|

|

4

|

Locate the Coordinate System Selection section. From the Coordinate system list, choose Cylindrical System 2 (sys2).

|

|

5

|

Locate the Constitutive Relation B-H section. From the Magnetization model list, choose Remanent flux density.

|

|

6

|

|

1

|

|

2

|

|

3

|

Locate the Domain Selection section. From the Selection list, choose Even magnets (Internal Rotor – Surface Mounted Magnets 1).

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click the Custom button.

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

In the Settings window for Study, type Study 1: Initial angle parametric sweep at DC current in the Label text field.

|

|

1

|

In the Model Builder window, under Study 1: Initial angle parametric sweep at DC current click Step 1: Stationary.

|

|

2

|

|

3

|

Select the Plot check box.

|

|

4

|

|

5

|

Click

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

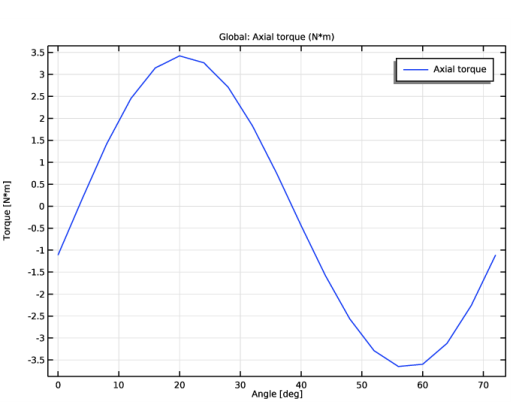

In the associated text field, type Angle [deg].

|

|

5

|

|

6

|

In the associated text field, type Torque [N*m].

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Select the Description check box.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 2: Synchronous rotation>Solver Configurations>Solution 2 (sol2)>Time-Dependent Solver 1 node, then click Fully Coupled 1.

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Rotating Machinery, Magnetic, click to expand the Discretization section.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 click Internal Rotor – Surface Mounted Magnets 1 (pi1).

|

|

2

|

|

4

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Air Gap Radial Magnetic Flux Density in the Label text field.

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 2: Synchronous rotation/Solution 2 (sol2).

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Time to Frequency Losses.

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Study, type Study 3: Loss calculation over full rotation in the Label text field.

|

|

1

|

In the Model Builder window, under Study 3: Loss calculation over full rotation click Step 1: Time to Frequency Losses.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|