|

|

1

|

|

2

|

In the Select Physics tree, select AC/DC>Magnetic Fields, No Currents>Magnetic Fields, No Currents, Boundary Elements (mfncbe).

|

|

3

|

Click Add.

|

|

4

|

In the Select Physics tree, select AC/DC>Magnetic Fields, No Currents>Magnetic Fields, No Currents (mfnc).

|

|

5

|

Click Add.

|

|

6

|

In the Select Physics tree, select AC/DC>Magnetic Fields, No Currents>Magnetic Fields, No Currents, Boundary Elements (mfncbe).

|

|

7

|

Click Add.

|

|

8

|

Click

|

|

9

|

|

10

|

Click

|

|

1

|

|

2

|

Browse to the model’s Application Libraries folder and double-click the file force_calculation_01_introduction.mph.

|

|

3

|

In the Insert Sequence from File dialog box, select Geometry 2 (Magnetic Torque Verification) in the Select geometry sequence to insert list.

|

|

4

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file force_calculation_c_mtorque_parameters.txt.

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Paste Selection dialog box, type 17, 19, 22, 24, 42-45 in the Selection text field (that is, the boundaries comprising the pole fillets).

|

|

6

|

Click OK.

|

|

7

|

|

1

|

|

2

|

|

3

|

Select Domains 2–4 only (that is, both the magnetized rod, as well as the domain enclosing it).

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Paste Selection dialog box, type 1-5, 54 in the Selection text field (that is, the boundaries comprising the cube).

|

|

6

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) click Magnetic Fields, No Currents, Boundary Elements (mfncbe).

|

|

2

|

In the Settings window for Magnetic Fields, No Currents, Boundary Elements, locate the Domain Selection section.

|

|

3

|

|

4

|

|

5

|

In the Paste Selection dialog box, type -1, 1-4 in the Selection text field (that is, everything except the infinite void). Notice that finite voids are indicated with a negative domain number. The infinite void is numbered 0.

|

|

6

|

Click OK.

|

|

7

|

|

8

|

In the Show More Options dialog box, in the tree, select the check box for the node Physics>Advanced Physics Options.

|

|

9

|

Click OK.

|

|

10

|

In the Settings window for Magnetic Fields, No Currents, Boundary Elements, click to expand the Far-Field Approximation section.

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Constitutive Relation B-H section. From the Magnetization model list, choose Remanent flux density.

|

|

5

|

|

6

|

Specify the e vector as

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Constitutive Relation B-H section. From the Magnetization model list, choose Remanent flux density.

|

|

5

|

|

6

|

Specify the e vector as

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, under Component 1 (comp1) click Magnetic Fields, No Currents, Boundary Elements 2 (mfncbe2).

|

|

2

|

In the Settings window for Magnetic Fields, No Currents, Boundary Elements, locate the Domain Selection section.

|

|

3

|

|

4

|

|

5

|

In the Paste Selection dialog box, type -1 in the Selection text field (that is, just the finite void).

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Physics toolbar, click

|

|

2

|

In the Settings window for Magnetic Scalar-Scalar Potential Coupling, locate the Coupled Interfaces section.

|

|

3

|

From the Secondary interface (magnetic scalar potential) list, choose Magnetic Fields, No Currents, Boundary Elements 2 (mfncbe2).

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

In the table, enter the following settings (make sure the parameter unit is cleared):

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

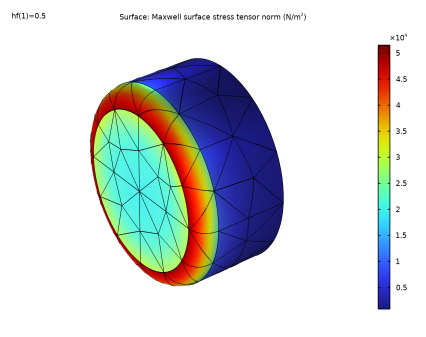

In the Settings window for 3D Plot Group, type Maxwell Surface Stress Tensor (BEM Rod) in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

In the Expression text field, type sqrt(mfncbe.nTx_BEM_rod^2+mfncbe.nTy_BEM_rod^2+mfncbe.nTz_BEM_rod^2).

|

|

4

|

Select the Description check box.

|

|

5

|

In the associated text field, type Maxwell surface stress tensor norm.

|

|

6

|

|

7

|

|

1

|

In the Model Builder window, right-click Maxwell Surface Stress Tensor (BEM Rod) and choose Surface.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Select the Wireframe check box.

|

|

8

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Maxwell Surface Stress Tensor (BEM Probe) in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

3

|

In the Expression text field, type sqrt(mfncbe.nTx_BEM_probe^2+mfncbe.nTy_BEM_probe^2+mfncbe.nTz_BEM_probe^2).

|

|

4

|

Select the Description check box.

|

|

5

|

In the associated text field, type Maxwell surface stress tensor norm.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|

Click

|

|

1

|

Go to the Table window.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Meshes right-click Mesh 2 and choose Build All.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Find the Physics interfaces in study and Multiphysics couplings in study subsections. In the tables, enter the following settings:

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

In the table, enter the following settings (make sure the parameter unit is cleared):

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

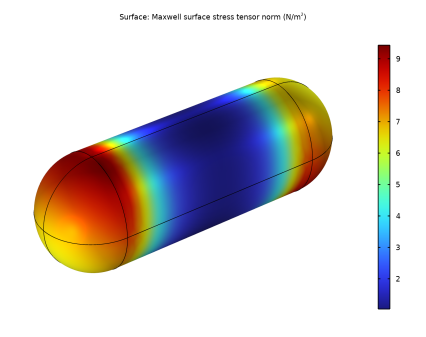

In the Settings window for 3D Plot Group, type Maxwell Surface Stress Tensor (FEM Rod) in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Select the Description check box.

|

|

5

|

In the associated text field, type Maxwell surface stress tensor norm.

|

|

6

|

|

7

|

|

1

|

In the Model Builder window, right-click Maxwell Surface Stress Tensor (FEM Rod) and choose Surface.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Select the Wireframe check box.

|

|

8

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Maxwell Surface Stress Tensor (FEM Probe) in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

In the Expression text field, type sqrt(mfnc.nTx_FEM_probe^2+mfnc.nTy_FEM_probe^2+mfnc.nTz_FEM_probe^2).

|

|

4

|

Select the Description check box.

|

|

5

|

In the associated text field, type Maxwell surface stress tensor norm.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|

Click

|

|

1

|

Go to the Table window.

|

|

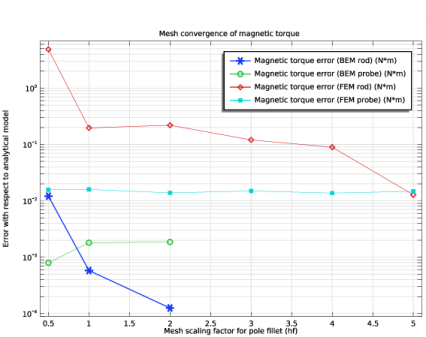

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

In the associated text field, type Mesh scaling factor for pole fillet (hf).

|

|

7

|

|

8

|

In the associated text field, type Error with respect to analytical model.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coloring and Style section. Find the Line markers subsection. From the Marker list, choose Cycle.

|

|

5

|

|

6

|

|

7

|

|

8

|