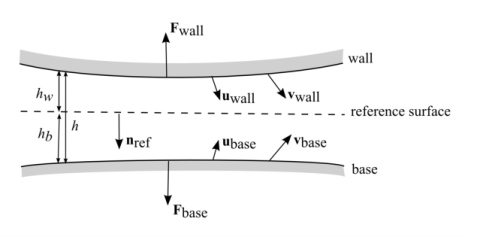

Figure 9-2 shows a typical configuration for the flow of fluid in a thin layer. The upper boundary is referred to as the wall, and the lower boundary is referred to as the base. Damping or lubrication forces operate on both surfaces.

In many cases the gap is sufficiently small for the flow in the thin film to be isothermal. Usually the gap thickness, h, is much smaller than the lateral dimensions of the geometry,

L. If this is the case it is possible to neglect inertial effects in the fluid in comparison to viscous effects (for MEMS devices this assumption is reasonable below MHz frequencies). Additionally, the curvature of the reference surface can be ignored when

h/

L«1. Under these assumptions the

Reynolds equation applies. For gas flows under the same conditions it is possible to derive a modified form of the Reynolds Equation, which uses the ideal gas law to eliminate the density from the equation system. Such a

modified Reynolds equation can even be adapted to model the flow of rarefied gases.

Different terminology is used for thin-film flow in different fields of physics. In tribology the term lubrication is frequently used, especially when the fluid is a liquid. In resonant MEMS devices, flow in the thin layer of gas separating a device from the substrate on which it is fabricated often provides significant

damping. In this case there is usually a distinction between

squeeze-film damping, when the direction of motion of the structure is predominantly perpendicular to the reference plane, and

slide-film damping for motion predominantly parallel to the reference plane.