You are viewing the documentation for an older COMSOL version. The latest version is

available here.

The Laminar Two-Phase Flow, Phase Field, (

)

and

Turbulent Two-Phase Flow, Phase Field, (

) interfaces contain a multiphysics coupling feature,

Two-Phase Flow, Phase Field, which is added automatically.

The Two-Phase Flow, Phase Field multiphysics coupling feature defines the density and dynamic viscosity of the fluid used in the

Laminar Flow and

Turbulent Flow interfaces, and it defines the surface tension on the interface in form of a volume force used in the momentum equation. It also enables the

Phase Field interface to use the velocity field calculated from the

Laminar Flow or

Turbulent Flow interface to transport the interface.

The Label is the default multiphysics coupling feature name.

The Name is used primarily as a scope prefix for variables defined by the coupling node. Refer to such variables in expressions using the pattern

<name>.<variable_name>. In order to distinguish between variables belonging to different coupling nodes or physics interfaces, the

name string must be unique. Only letters, numbers, and underscores (_) are permitted in the

Name field. The first character must be a letter.

The default Name (for the first multiphysics coupling feature

Two-Phase Flow, Phase Field in the model) is

tpf1.

When nodes are added from the context menu, you can select All domains (the default) or select

Manual from the

Selection list to choose specific domains.

By default, the Temperature model input is set to

Common model input, and the temperature is controlled from

Default Model Inputs under

Global Definitions or by a locally defined

Model Input. If a Heat Transfer interface is included in the component, it controls the temperature

Common model input. Alternatively, the temperature field can be selected from another physics interface. All physics interfaces have their own tags (

Name). For example, if a Heat Transfer in Fluids interface is included in the component, the

Temperature (ht) option is available for

T.

You can also select User defined from the

Temperature model input in order to manually prescribe

T.

This input appears when a material requires the absolute pressure as a model input. The default Absolute pressure pA is

p+pref, where

p is the dependent pressure variable from the Navier–Stokes or RANS equations, and

pref is from the user input defined at the fluid flow physics interface level.

The Absolute pressure field can be edited by clicking

Make All Model Inputs Editable (

) and entering the desired value in the input field.

To specify the properties of Fluid 1from a material, select the appropriate material in the

Fluid 1 list. Also make sure that the

Density of fluid 1ρ1 and

Dynamic viscosity of fluid 1μ1 are both set to

From Material.

The non-Newtonian Power law, Carreau––, Bingham–Papanastasiou, Herschel–Bulkley–Papanastasiou, and Casson–Papanastasiou–––– models can alternatively be used to specify the dynamic viscosities of the two fluids.

To instead apply a variable or expression for the density or dynamic viscosity for Fluid A, select User defined in the

Density of fluid 1 ρ1 or the

Dynamic viscosity of fluid 1 μ1 list and enter the expression in the corresponding text field.

Similarly, the properties of Fluid 2 can be specified. The default material is set to

None.

|

|

Care should be taken when using the Domain Material setting for the material properties for Fluid 1 and Fluid 2. The material properties are obtained from the domain irrespective of the location of the interface. If two different materials are selected in domains 1 and 2, with the phase boundary initially coincident with the domain boundary, the model has convergence issues once the phase boundary moves away from the domain boundary. This is because a density discontinuity and a viscosity discontinuity occurs at the boundary separating the two fluids. For this reason, selecting the material directly is recommended when setting the material properties for Fluid 1 and Fluid 2.

|

Select the method used for Density averaging and

Viscosity averaging. The default method for both settings is

Volume average. In addition to the default method,

Density averaging can be set to

Heaviside function or

Harmonic volume average, while

Viscosity averaging can be set to

Heaviside function,

Harmonic volume average,

Mass average or

Harmonic mass average. When a

Heaviside function is used, enter a value for the corresponding mixing parameter,

lρ or

lμ. The

Shift surface tension force to the heaviest phase check-box can be selected to diminish smoothing effects on the surface-tension force, that may result in unphysical, strong acceleration of a much lighter phase. When selected, enter a value for the

Smoothing factor,

ds,Fst.

When the surface tension force is included in the momentum equation, you can select the Shift surface tension force to the heaviest phase check box. This can prevent significant spurious oscillations in the velocity field for the lighter phase in cases with a large difference in density between the two phases. The amount of shifting is controlled by the

Smoothing factor ds,Fst (default

0.1). The surface tension force is then multiplied by

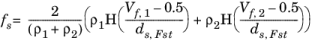

(6-2)

Shift surface tension force to the heaviest phase works better when combined with

Heaviside function for the averaging of density and viscosity.

Select the Include surface tension force in momentum equation check box to include the surface tension force in the momentum equation. If the surface tension force is included, select

Include surface tension gradient effects in surface tension force to account for the Marangoni effect due to gradients in the surface tension coefficient.

Select a Surface tension coefficient σ (SI unit: N/m):

|

•

|

To use a predefined expression, select Library coefficient, liquid/gas interface or Library coefficient, liquid/liquid interface. Then select an option from the list that displays below (for example, Water/Air or Glycerol/Air).

|

|

•

|

For User defined, enter a value or expression for the surface tension coefficient σ (SI unit: N/m).

|