|

|

10-7 s

|

||

|

10-6 s

|

||

|

3.16·10-6 s

|

||

|

10-5 s

|

||

|

3.16·10-5 s

|

||

|

10-4 s

|

||

|

3.16·10-4 s

|

||

|

10-3 s

|

||

|

3.16·10-3 s

|

||

|

10-2 s

|

||

|

3.16·10-2 s

|

||

|

8.25·10-2 MPa

|

||

|

3.73·10-2 MPa

|

||

|

1.18·10-2 MPa

|

||

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

Click Browse.

|

|

4

|

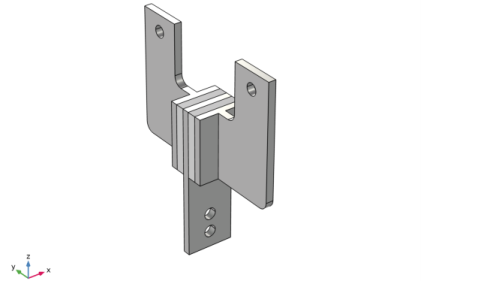

Browse to the model’s Application Libraries folder and double-click the file viscoelastic_damper.mphbin.

|

|

5

|

Click Import.

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Solid Mechanics (solid) and choose Material Models>Linear Elastic Material.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

Click

|

|

5

|

|

6

|

Browse to the model’s Application Libraries folder and double-click the file viscoelastic_damper_viscoelastic_data.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

7

|

|

8

|

Select the Cutoff check box.

|

|

9

|

|

10

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 1 node, then click Auxiliary pressure (comp1.solid.pw).

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Find the Algebraic variable settings subsection. From the Error estimation list, choose Exclude algebraic.

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Displacement>Displacement field - m>w - Displacement field, Z component.

|

|

3

|

|

4

|

|

1

|

|

2

|

Select the Plot check box.

|

|

1

|

|

2

|

|

3

|

Click Import.

|

|

4

|

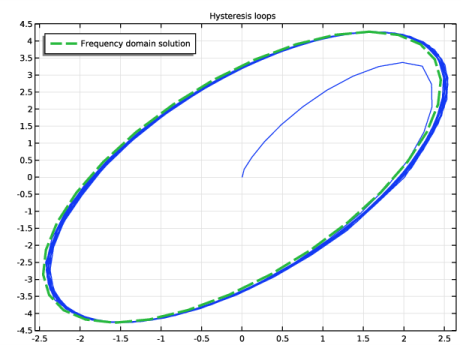

Browse to the model’s Application Libraries folder and double-click the file viscoelastic_damper_frequency_solution.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

Click Replace Expression in the upper-right corner of the x-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Displacement>Displacement field - m>w - Displacement field, Z component.

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|