|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Select the object pol1 only.

|

|

3

|

|

1

|

|

2

|

Select the object r1 only.

|

|

3

|

|

4

|

|

5

|

Select the object copy1 only.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Solid Mechanics (solid) and choose Volume Forces>Body Load.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

From the list, choose Diagonal.

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Click

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1 node, then click Parametric 1.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

15

|

|

16

|

|

1

|

|

2

|

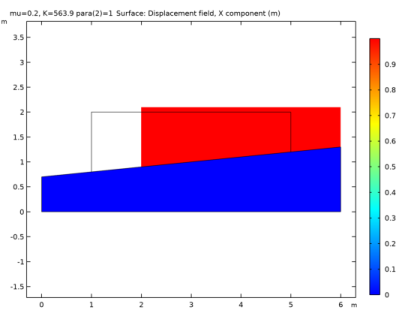

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Displacement>Displacement field - m>u - Displacement field, X component.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Point Evaluation, type Point Evaluation: Penalty in the Label text field.

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 1: Penalty/Parametric Solutions 1 (sol2).

|

|

4

|

|

5

|

|

7

|

Click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Displacement>Displacement field - m>u - Displacement field, X component.

|

|

8

|

Click

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Solid Mechanics (solid) right-click Contact 1 and choose Duplicate.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Click

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Physics and variables selection tree, select Component 1 (comp1)>Solid Mechanics (solid), Controls spatial frame>Contact 1.

|

|

5

|

Click

|

|

6

|

In the Physics and variables selection tree, select Component 1 (comp1)>Solid Mechanics (solid), Controls spatial frame>Contact 3.

|

|

7

|

Click

|

|

8

|

|

9

|

Click

|

|

11

|

|

12

|

In the Settings window for Study, type Study 2: Augmented Lagrangian, Segregated in the Label text field.

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 2: Augmented Lagrangian, Segregated>Solver Configurations>Solution 6 (sol6)>Dependent Variables 1 node, then click Friction force (spatial frame) (comp1.solid.Tt_ap1).

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

In the Model Builder window, expand the Study 2: Augmented Lagrangian, Segregated>Solver Configurations>Solution 6 (sol6)>Stationary Solver 1 node, then click Parametric 1.

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

1

|

In the Model Builder window, expand the Displacement: Augmented Lagrangian, Segregated node, then click Surface 1.

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Displacement>Displacement field - m>u - Displacement field, X component.

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Group, type Applied Loads: Augmented Lagrangian, Segregated in the Label text field.

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Contact: Augmented Lagrangian, Segregated in the Label text field.

|

|

1

|

In the Model Builder window, expand the Contact: Augmented Lagrangian, Segregated node, then click Gray Surfaces.

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Point Evaluation, type Point Evaluation: Augmented Lagrangian, Segregated in the Label text field.

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 2: Augmented Lagrangian, Segregated/Parametric Solutions 2 (sol7).

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Physics and variables selection tree, select Component 1 (comp1)>Solid Mechanics (solid), Controls spatial frame>Contact 2.

|

|

5

|

Click

|

|

6

|

In the Physics and variables selection tree, select Component 1 (comp1)>Solid Mechanics (solid), Controls spatial frame>Contact 3.

|

|

7

|

Click

|