|

|

•

|

|

•

|

|

•

|

|

•

|

|

•

|

|

•

|

|

•

|

|

•

|

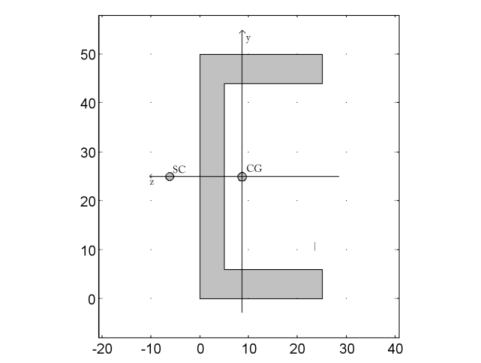

Locations for axial stress evaluation are positioned at the outermost corners of the profile at the points

(y1, z1)=(−0.025, −0.0164) (y2, z2)=(0.025, −0.0164) (y3, z3)=(0.025, 0.0086), (y4, z4)=(−0.025, 0.0086) measured in the local coordinate system. The indices of the coordinates are point identifiers. |

|

•

|

|

•

|

|

•

|

|

•

|

|

•

|

|

•

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, right-click Global Definitions and choose Load and Constraint Groups>Load Group.

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

1

|

|

2

|

|

3

|

Locate the Definition section. In the Expression text field, type -FZ*L*y/comp1.Izz+FY*L*z/comp1.Iyy.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

Click OK.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

Specify the V vector as

|

|

1

|

|

3

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

|

7

|

|

8

|

Click OK.

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Point Evaluation, type Case1: Displacement/Rotation in the Label text field.

|

|

3

|

|

5

|

Click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Displacement>Displacement field - m>u - Displacement field, x component.

|

|

6

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Definitions>Variables>deltaX - X displacement - m.

|

|

7

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Displacement>Displacement field - m>v - Displacement field, y component.

|

|

8

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Definitions>Variables>deltaY - Y displacement - m.

|

|

9

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Displacement>Displacement field - m>w - Displacement field, z component.

|

|

10

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Definitions>Variables>deltaZ - Z displacement - m.

|

|

11

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Displacement>Rotation field - rad>thx - Rotation field, X component.

|

|

12

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Definitions>Variables>thetaX - Twist.

|

|

13

|

Locate the Expressions section. In the table, enter the following settings:

|

|

14

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Point Evaluation, type Case2: Displacement/Rotation in the Label text field.

|

|

4

|

|

5

|

Click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Displacement>Displacement field - m>w - Displacement field, z component.

|

|

6

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Definitions>Variables>deltaZ_g - Z displacement due to gravity load - m.

|

|

7

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Displacement>Rotation field - rad>thx - Rotation field, X component.

|

|

8

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Definitions>Variables>thetaX_g - Twist due to gravity load.

|

|

9

|

Locate the Expressions section. In the table, enter the following settings:

|

|

10

|

Click

|

|

1

|

|

2

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

Click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Stress>Stress variables at first evaluation point>beam.s1 - Normal stress at first evaluation point - N/m².

|

|

7

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Stress>Stress variables at second evaluation point>beam.s2 - Normal stress at second evaluation point - N/m².

|

|

8

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Stress>Stress variables at third evaluation point>beam.s3 - Normal stress at third evaluation point - N/m².

|

|

9

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Stress>Stress variables at fourth evaluation point>beam.s4 - Normal stress at fourth evaluation point - N/m².

|

|

10

|

Locate the Expressions section. In the table, enter the following settings:

|

|

11

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

5

|

Click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Stress>Stress variables at first evaluation point>beam.sb1 - Bending stress at first evaluation point - N/m².

|

|

6

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Definitions>Functions>sigmabx(y, z) - sigmabx.

|

|

7

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Stress>Stress variables at second evaluation point>beam.sb2 - Bending stress at second evaluation point - N/m².

|

|

8

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Definitions>Functions>sigmabx(y, z) - sigmabx.

|

|

9

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Stress>Stress variables at third evaluation point>beam.sb3 - Bending stress at third evaluation point - N/m².

|

|

10

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Definitions>Functions>sigmabx(y, z) - sigmabx.

|

|

11

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Stress>Stress variables at fourth evaluation point>beam.sb4 - Bending stress at fourth evaluation point - N/m².

|

|

12

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Definitions>Functions>sigmabx(y, z) - sigmabx.

|

|

13

|

Locate the Expressions section. In the table, enter the following settings:

|

|

14

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

5

|

Click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Stress>beam.tsymax - Max shear stress from shear force, y direction - N/m².

|

|

6

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Definitions>Variables>tausy_max - Maximum shear stress due y force - N/m².

|

|

7

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Stress>beam.tszmax - Max shear stress from shear force, z direction - N/m².

|

|

8

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Definitions>Variables>tausz_max - Maximum shear stress due to z force - N/m².

|

|

9

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Stress>beam.ttmax - Max torsional shear stress - N/m².

|

|

10

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Definitions>Variables>taut_max - Shear stress due to torsion - N/m².

|

|

11

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Stress>beam.txymax - Max shear stress, y direction - N/m².

|

|

12

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Definitions>Variables>tauxy_max - Maximum shear stress, y component - N/m².

|

|

13

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Stress>beam.txzmax - Max shear stress, z direction - N/m².

|

|

14

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Definitions>Variables>tauxz_max - Maximum shear stress, z component - N/m².

|

|

15

|

Locate the Expressions section. In the table, enter the following settings:

|

|

16

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check boxes for Stationary Study: Beam and Eigenfrequency Study: Beam.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Beam (beam).

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

In the Rename Study dialog box, type Stationary Study: Beam Cross Section in the New label text field.

|

|

3

|

Click OK.

|

|

1

|

|

2

|

In the Part Libraries window, select Structural Mechanics Module>Beams>Generic>C_beam_generic in the tree.

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click OK.

|

|

1

|

|

2

|

Copy the following code into the EvaluateSectionForces window:

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

1

|

In the Model Builder window, expand the Cross-Section Data 2 node, then click Section Orientation 1.

|

|

2

|

|

3

|

Specify the P vector as

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Beam Cross Section (bcs).

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Rename Study dialog box, type Stationary Study: Beam (Inputs from Beam Cross Section) in the New label text field.

|

|

6

|

Click OK.

|

|

1

|

|

2

|

Find the Values of variables not solved for subsection. From the Settings list, choose User controlled.

|

|

3

|

|

4

|

|

5

|

|

6

|

Click

|

|

8

|

|

1

|

|

2

|

|

3

|

|

5

|

Click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Beam>Stress>beam.mises - von Mises stress - N/m².

|

|

6

|

Locate the Expressions section. In the table, enter the following settings:

|

|

7

|

Click

|

|

8

|

Locate the Data section. From the Dataset list, choose Stationary Study: Beam (Inputs from Beam Cross Section)/Solution 4 (5) (sol4).

|

|

9

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Physics and variables selection tree, select Component 1 (comp1)>Beam (beam)>Cross-Section Data 2.

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Physics and variables selection tree, select Component 1 (comp1)>Beam (beam)>Cross-Section Data 2.

|

|

5

|

Click

|