|

|

1

|

In the Model Wizard window, The first step to build a model is to open COMSOL and then specify the type of analysis you want to do - in this case, a stationary, solid mechanics analysis.

|

|

2

|

click

|

|

3

|

|

4

|

Click Add.

|

|

5

|

Click

|

|

6

|

|

7

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Browse.

|

|

6

|

Click Import.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. From the Contribute to list, choose Partition Block.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. From the Contribute to list, choose Partition Block.

|

|

8

|

|

1

|

|

2

|

Select the object imp1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

6

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Solid Mechanics (solid) and choose Fixed Constraint.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coordinate System Selection section. From the Coordinate system list, choose Boundary System 1 (sys1).

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

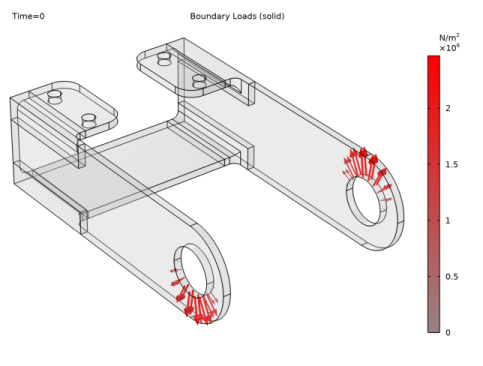

In the Model Builder window, expand the Results>Applied Loads (solid) node, then click Boundary Loads (solid).

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

6

|

|

7

|

|

8

|

Clear the Color check box.

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

In the Settings window for Evaluation Group, type Evaluation Group: Reactions in the Label text field.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Reactions>Reaction force (spatial frame) - N>All expressions in this group.

|

|

5

|

Locate the Expressions section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|