|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Semiconductor Equilibrium.

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

In the Settings window for Interpolation, type Interpolation 1: solar spectrum in the Label text field.

|

|

3

|

|

4

|

Click Browse.

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file si_solar_cell_1d_AM15_approx.txt.

|

|

6

|

Find the Functions subsection. In the table, enter the following settings:

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

In the Settings window for Interpolation, type Interpolation 2: Si absorption spectrum in the Label text field.

|

|

3

|

|

4

|

Click Browse.

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file si_solar_cell_1d_n_k_data.txt.

|

|

6

|

|

7

|

Find the Functions subsection. In the table, enter the following settings:

|

|

8

|

|

9

|

|

10

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, expand the Geometric Doping Model 1 node, then click Boundary Selection for Doping Profile 1.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Semiconductor>Carriers and dopants>Dopant concentrations>semi.Nd - Donor concentration - 1/m³.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

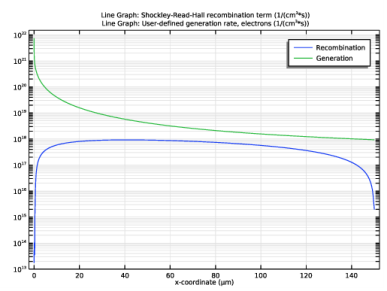

In the Settings window for 1D Plot Group, type Generation/Recombination rates in the Label text field.

|

|

3

|

|

1

|

In the Model Builder window, expand the Generation/Recombination rates node, then click Line Graph 1.

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Semiconductor>Generation and recombination>semi.Rsrh - Shockley-Read-Hall recombination term - 1/(m³·s).

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

In the Model Builder window, under Results>Generation/Recombination rates right-click Line Graph 1 and choose Duplicate.

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Semiconductor>Generation and recombination>semi.udg1.Gn - User-defined generation rate, electrons - 1/(m³·s).

|

|

3

|

Locate the Legends section. In the table, enter the following settings:

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

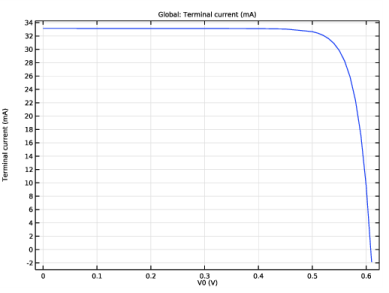

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Semiconductor>Terminals>semi.I0_1 - Terminal current - A.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|