|

|

205 GPa

|

|

|

7800 kg/m3

|

|

|

0.15 m

|

|

|

0.1 L

|

|

|

0.3 L

|

|

|

0.7 L

|

|

|

0.9 L

|

|

|

1.4 kg

|

|

|

1

|

|

2

|

In the Select Physics tree, select Structural Mechanics>Rotordynamics>Beam Rotor with Hydrodynamic Bearing.

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file turbocharger_transient_analysis_rotor_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file turbocharger_transient_analysis_bearing_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. Click New.

|

|

8

|

|

9

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. Click New.

|

|

9

|

|

10

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. From the Contribute to list, choose Bearing Surface.

|

|

1

|

|

2

|

Select the object cyl5 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. Click New.

|

|

7

|

|

8

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select all objects.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

Locate the Input section. Find the Input objects subsection. Select the

|

|

10

|

|

11

|

|

12

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Add dialog box, in the Selections to add list, choose Inner film, bearing 1 and Outer film, bearing 1.

|

|

6

|

Click OK.

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

In the Add dialog box, in the Selections to add list, choose Inner film, bearing 2 and Outer film, bearing 2.

|

|

8

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Add dialog box, in the Selections to add list, choose Inner film, bearing 1 and Inner film, bearing 2.

|

|

6

|

Click OK.

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

In the Add dialog box, in the Selections to add list, choose Outer film, bearing 1 and Outer film, bearing 2.

|

|

8

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

Right-click and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Definitions>Selections click Channel, outer film, bearing 1.1.

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Beam Rotor (rotbm) click Rotor Cross Section 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Locate the Disk Properties section. From the Center of mass list, choose Offset from selected points.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

From the list, choose Diagonal.

|

|

6

|

|

7

|

Locate the Fluid Properties section. From the μ list, choose User defined. In the associated text field, type mu0.

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Floating Ring Bearing 1 node, then click Inner Film Properties 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Channel, Outer Film section. From the Selection list, choose Channel, outer film, bearing 1.

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Floating Ring Bearing 2 node, then click Inner Film Properties 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Channel, Outer Film section. From the Selection list, choose Channel, outer film, bearing 2.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Multiphysics click Beam Rotor Bearing Coupling 1 (brbc1).

|

|

2

|

|

3

|

|

1

|

Right-click Component 1 (comp1)>Multiphysics>Beam Rotor Bearing Coupling 1 (brbc1) and choose Duplicate.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the associated text field, type Torque (N*m).

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Fluid loads>Fluid moment on ring, inner film - N·m>hdb.frb2.Mr_inx - Fluid moment on ring, inner film, x component.

|

|

3

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Fluid loads>Fluid moment on ring, outer film - N·m>hdb.frb2.Mr_outx - Fluid moment on ring, outer film, x component.

|

|

4

|

|

5

|

|

6

|

|

7

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the associated text field, type Scaled y displacement.

|

|

6

|

|

7

|

In the associated text field, type Scaled z displacement.

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Floating Ring Bearing 1>Journal displacement relative to ring (scaled)>hdb.frb1.uJRz_rel - Journal displacement relative to ring (scaled), z component.

|

|

3

|

|

4

|

Click Replace Expression in the upper-right corner of the x-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Floating Ring Bearing 1>Journal displacement relative to ring (scaled)>hdb.frb1.uJRy_rel - Journal displacement relative to ring (scaled), y component.

|

|

5

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Floating Ring Bearing 2>Journal displacement relative to ring (scaled)>hdb.frb2.uJRz_rel - Journal displacement relative to ring (scaled), z component.

|

|

3

|

Click Replace Expression in the upper-right corner of the x-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Floating Ring Bearing 2>Journal displacement relative to ring (scaled)>hdb.frb2.uJRy_rel - Journal displacement relative to ring (scaled), y component.

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the associated text field, type Scaled y displacement.

|

|

6

|

|

7

|

In the associated text field, type Scaled z displacement.

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Floating Ring Bearing 1>Ring displacement relative to bearing (scaled)>hdb.frb1.uRBz_rel - Ring displacement relative to bearing (scaled), z component.

|

|

3

|

Click Replace Expression in the upper-right corner of the x-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Floating Ring Bearing 1>Ring displacement relative to bearing (scaled)>hdb.frb1.uRBy_rel - Ring displacement relative to bearing (scaled), y component.

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Floating Ring Bearing 2>Ring displacement relative to bearing (scaled)>hdb.frb2.uRBz_rel - Ring displacement relative to bearing (scaled), z component.

|

|

3

|

Click Replace Expression in the upper-right corner of the x-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Floating Ring Bearing 2>Ring displacement relative to bearing (scaled)>hdb.frb2.uRBy_rel - Ring displacement relative to bearing (scaled), y component.

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

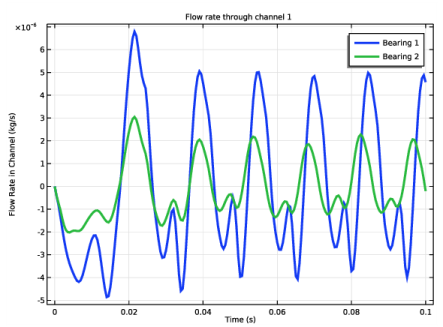

In the associated text field, type Flow Rate in Channel (kg/s).

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|