|

|

Density ρ

|

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

1

|

Right-click Component 1 (comp1)>Geometry 1>Work Plane 1 (wp1)>Plane Geometry>Circle 1 (c1) and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

Select the object del1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

4

|

Locate the Geometric Entity Selection section. From the Geometric entity level list, choose Boundary.

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

In the Show More Options dialog box, in the tree, select the check box for the node Physics>Advanced Physics Options.

|

|

3

|

Click OK.

|

|

4

|

|

5

|

|

6

|

Select the Cavitation check box.

|

|

7

|

|

8

|

|

9

|

In the Show More Options dialog box, in the tree, select the check box for the node Physics>Stabilization.

|

|

10

|

Click OK.

|

|

11

|

In the Settings window for Hydrodynamic Bearing, click to expand the Inconsistent Stabilization section.

|

|

12

|

|

1

|

|

2

|

In the Settings window for Hydrodynamic Thrust Bearing, locate the Reference Surface Properties section.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Locate the Fluid Properties section. From the μ list, choose User defined. In the associated text field, type 0.072[Pa*s].

|

|

8

|

|

9

|

Click in the Graphics window and then press Ctrl+A to select all boundaries.

|

|

1

|

|

2

|

|

3

|

|

4

|

Specify the Orientation vector defining local y direction vector as

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for Global Evaluation, click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Fluid loads>Fluid load on collar - N>hdb.htb1.Fcz - Fluid load on collar, z component.

|

|

3

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

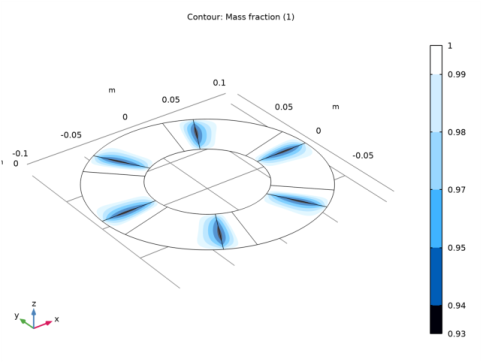

In the Settings window for Contour, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Cavitation>hdb.theta - Mass fraction.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click

|

|

6

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Pressure (Radial distribution) in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|