|

|

1

|

|

2

|

Browse to the model’s Application Libraries folder and double-click the file porous_microchannel_heat_sink_geom_sequence.mph.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Global Definitions right-click Materials and choose Blank Material.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Porous Matrix Properties section. From the Porous material list, choose Steel AISI 4340 (mat2).

|

|

6

|

|

7

|

|

8

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Heat Transfer in Solids and Fluids (ht) click Fluid 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

6

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

In the table, clear the Use check boxes for Heat Transfer in Solids and Fluids (ht) and Nonisothermal Flow 1 (nitf1). to build a mesh for the flow domains only.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Multiphysics>Stationary, One-Way NITF.

|

|

4

|

|

5

|

|

1

|

|

3

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

4

|

In the Physics and variables selection tree, select Component 1 (comp1)>Laminar Flow (spf)>Fluid and Matrix Properties 1.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

4

|

Click

|

|

1

|

|

2

|

|

3

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Multiphysics>Stationary, One-Way NITF.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Click

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click

|

|

7

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Results>Derived Values right-click Global Evaluation 1 and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

1

|

Go to the Table window.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

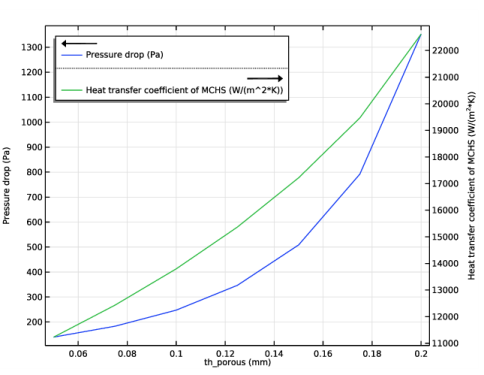

In the Settings window for 1D Plot Group, type Heat-Transfer Coefficient and Pressure Drop in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

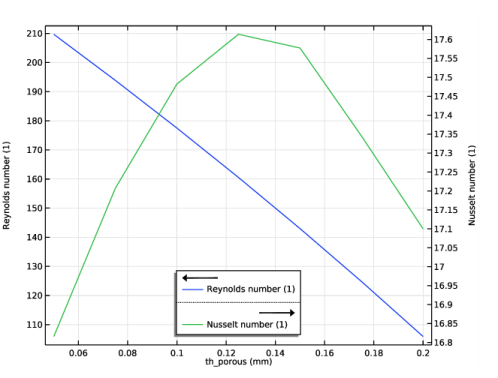

In the Settings window for 1D Plot Group, type Reynolds and Nusselt Numbers in the Label text field.

|

|

1

|

In the Model Builder window, expand the Reynolds and Nusselt Numbers node, then click Table Graph 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|

|

1

|

Go to the Table window.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Velocity and Temperature Fields in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Locate the Coloring and Style section. Find the Point style subsection. From the Type list, choose Arrow.

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|