|

|

1

|

|

2

|

In the Select Physics tree, select Fluid Flow>Multiphase Flow>Two-Phase Flow, Phase Field>Laminar Flow.

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

In the Select Study tree, select Preset Studies for Selected Multiphysics>Time Dependent with Phase Initialization.

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file slot_die_coating_2d_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

8

|

|

1

|

|

2

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

In the tree, select Built-in>Air.

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Multiphysics click Two-Phase Flow, Phase Field 1 (tpf1).

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Surface Tension section. From the Surface tension coefficient list, choose User defined. In the σ text field, type 0.49.

|

|

1

|

|

2

|

|

3

|

In the tree, select the check box for the node Polymer Flow Module>inelastic_non_newtonian_fluid_parameter_estimation.

|

|

4

|

Click

|

|

1

|

In the Model Builder window, under Global Definitions click Inelastic Non-Newtonian Fluid Parameter Estimation 1.

|

|

2

|

In the Settings window for Inelastic Non-Newtonian Fluid Parameter Estimation, click

|

|

3

|

Browse to the model’s Application Libraries folder and double-click the file slot_die_coating_2d_viscosity_input.txt.

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Laminar Flow (spf) and choose Wall.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Phase Field (pf) click Initial Values, Fluid 2.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Show More Options dialog box, in the tree, select the check box for the node Physics>Advanced Physics Options.

|

|

3

|

Click OK.

|

|

4

|

In the Model Builder window, under Component 1 (comp1)>Multiphysics click Two-Phase Flow, Phase Field 1 (tpf1).

|

|

5

|

In the Settings window for Two-Phase Flow, Phase Field, click to expand the Advanced Settings section.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

Select the Plot check box.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

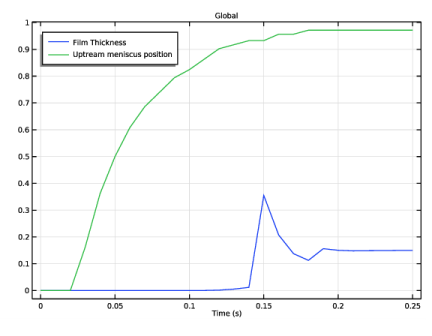

In the Settings window for 1D Plot Group, type Film Thickness and Upstream Meniscus Position in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

4

|