|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

|

5

|

Click Add.

|

|

6

|

|

7

|

Click Add.

|

|

8

|

|

9

|

Click Add.

|

|

10

|

Click Study.

|

|

11

|

|

12

|

Click Done.

|

|

1

|

|

2

|

Browse to the model’s Application Libraries folder and double-click the file ground_heat_recovery_geom_sequence.mph.

|

|

3

|

|

4

|

Click OK.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. Click New.

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

4

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. From the Contribute to list, choose Pipes.

|

|

1

|

|

2

|

Select the object pol1 only.

|

|

3

|

|

4

|

|

5

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. From the Contribute to list, choose Pipes.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. Click New.

|

|

8

|

|

9

|

Click OK.

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file ground_heat_recovery_T_surface.txt.

|

|

6

|

Locate the Interpolation and Extrapolation section. From the Interpolation list, choose Piecewise cubic.

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Select the Description check box.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Definition section. In the Expression text field, type T_z0(month[a]/12)[1/degC]+Tz_depth[m/K]*(-z).

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Plot.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Heat Transfer in Solids (ht) click Initial Values 1.

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Heat Transfer in Pipes (htp) click Heat Transfer 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

From the list, choose Circular.

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Heat Transfer in Pipes (htp) click Temperature 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

In the text field, type 3.25[mm].

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Reinitialization section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Reinitialization section. In the table, enter the following settings:

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Global ODEs and DAEs (ge) click Global Equations 1.

|

|

2

|

|

4

|

|

5

|

|

6

|

Click Filter.

|

|

7

|

|

8

|

Click OK.

|

|

9

|

|

10

|

|

11

|

|

12

|

Click Filter.

|

|

13

|

|

14

|

Click OK.

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

Click Filter.

|

|

7

|

|

8

|

Click OK.

|

|

1

|

|

2

|

|

3

|

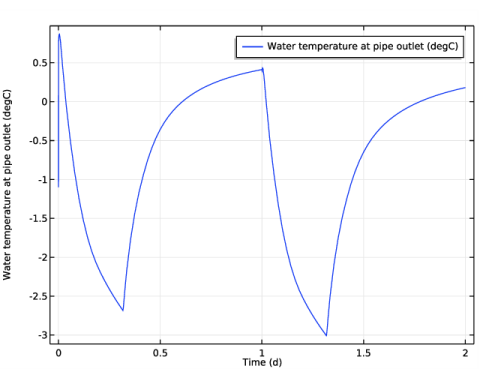

Click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Definitions>Variables>T_out - Water temperature at pipe outlet - K.

|

|

4

|

|

5

|

Click to expand the Table and Window Settings section. From the Output table list, choose New table.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

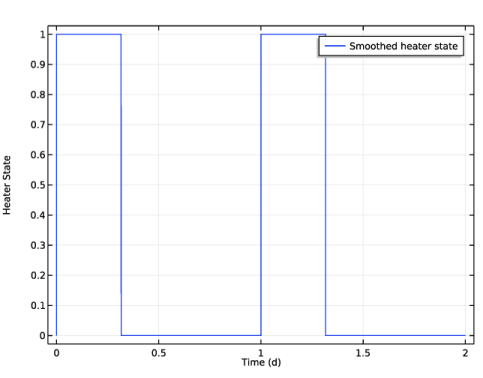

Click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Definitions>Variables>heater_state_smoothed - Smoothed heater state.

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Mesh 1 and choose More Operations>Edge.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

Click the Custom button.

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

Click the Custom button.

|

|

5

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Range.

|

|

5

|

|

6

|

|

7

|

Click Replace.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Time-Dependent Solver 1 node, then click Fully Coupled 1.

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Line, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1>Heat Transfer in Pipes>T2 - Temperature - K.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

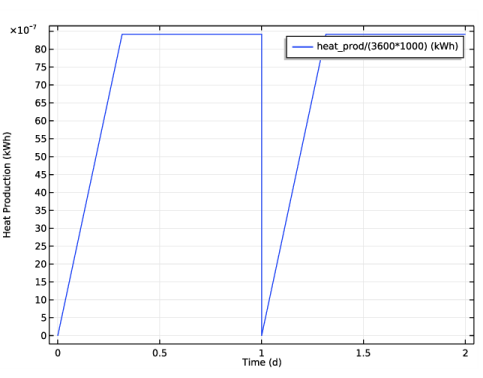

In the associated text field, type Heat Production (kWh).

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

In the associated text field, type Heater State.

|

|

5

|