|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coordinates section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

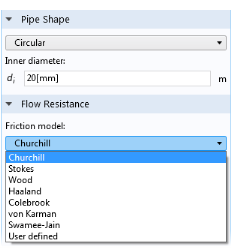

From the list, choose Circular.

|

|

4

|

|

5

|

Locate the Flow Resistance section. From the Surface roughness list, choose Galvanized iron (0.15 mm).

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Find the Show or hide all physics symbols subsection. Click Select All to display physics symbols for all features.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

In the Model Builder window, expand the Results>Velocity (pfl)>Arrow Line 1 node, then click Color Expression 1.

|

|

2

|

In the Settings window for Color Expression, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Pipe Flow>pfl.Re - Reynolds number.

|

|

3

|

|

4

|