|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, under Global Definitions>Mesh Parts right-click Mesh Part 1 and choose Build All.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Add dialog box, in the Selections to invert list, choose Load Boundary (Import 1), Symmetry y (Import 1), Symmetry x (Import 1), and Moving Boundaries.

|

|

6

|

Click OK.

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Optimization.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 2 (comp2) right-click Solid Mechanics 2 (solid2) and choose Roller.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Solid Mechanics (solid).

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Solid Mechanics (solid).

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click Add Expression in the upper-right corner of the Objective Function section. From the menu, choose Component 2 (comp2)>Solid Mechanics 2>Global>comp2.solid2.Ws_tot - Total elastic strain energy - J.

|

|

7

|

Locate the Objective Function section. From the Objective scaling list, choose Initial solution based.

|

|

8

|

Locate the Control Variables section. In the table, clear the Solve for check box for Density Model 1 (dtopo1).

|

|

9

|

Click Add Expression in the upper-right corner of the Constraints section. From the menu, choose Component 2 (comp2)>Definitions>Free Shape Domain 1>comp2.fsd1.area - Free shape area.

|

|

10

|

Locate the Constraints section. In the table, enter the following settings:

|

|

11

|

|

1

|

|

2

|

|

3

|

Select the Plot check box.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Shape Optimization (alternative plot) in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

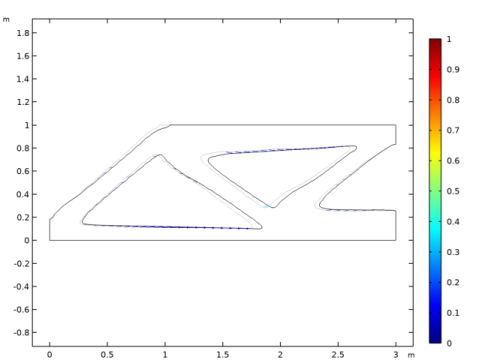

In the Settings window for 2D Plot Group, type Shaped Optimized Stress (solid2) in the Label text field.

|