|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Optimization>Topology Optimization, Stationary.

|

|

6

|

Click

|

|

1

|

|

2

|

Browse to the model’s Application Libraries folder and double-click the file hook_optimization_stl_geom_sequence.mph.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Definitions>Topology Optimization click Density Model 1 (dtopo1).

|

|

2

|

|

3

|

|

4

|

|

5

|

In the text field, type Lmin.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Prescribed Material Boundary, locate the Geometric Entity Selection section.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

Click

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Constraints section. In the table, enter the following settings:

|

|

5

|

|

6

|

|

7

|

|

1

|

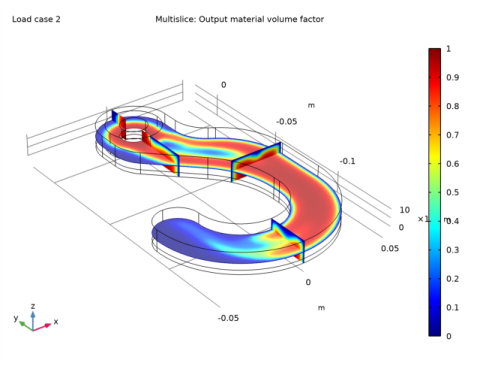

In the Model Builder window, under Results>Topology Optimization click Output material volume factor.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Solid Mechanics (solid).

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, expand the Solution 2 (sol2) node, then click Smooth Design (mesh2)>Step 1: Stationary.

|

|

2

|

|

3

|

Find the Initial values of variables solved for subsection. From the Settings list, choose User controlled.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click Import.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Solid Mechanics (solid) and choose Copy.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, expand the Solid Mechanics (solid2) node, then click Fixed Constraint 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Solid Mechanics (solid).

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

4

|

|

5

|

Click

|

|

6

|

Click

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|