|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Solid Mechanics (solid) and choose Fixed Constraint.

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Hyperelastic Material, type Polynomial, Two Parameters in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Hyperelastic Material section. From the Material model list, choose Mooney-Rivlin, two parameters.

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

In the Settings window for Hyperelastic Material, type Polynomial, Five Parameters in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Physics and variables selection tree, select Component 1 (comp1)>Solid Mechanics (solid), Controls spatial frame>Mooney-Rivlin and Component 1 (comp1)>Solid Mechanics (solid), Controls spatial frame>Polynomial, Five Parameters.

|

|

5

|

Click

|

|

6

|

|

1

|

In the Model Builder window, expand the Stress (Polynomial, Two Parameters) node, then click Surface 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Displacement>Displacement field - m>v - Displacement field, Y component.

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

In the Physics and variables selection tree, select Component 1 (comp1)>Solid Mechanics (solid), Controls spatial frame>Polynomial, Five Parameters.

|

|

4

|

Click

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Stress (Polynomial, Five Parameters) node, then click Surface 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

1

|

|

2

|

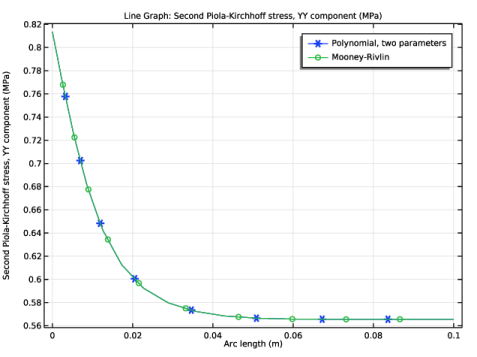

In the Settings window for 1D Plot Group, type Second Piola-Kirchhoff Stress, Y component in the Label text field.

|

|

1

|

|

3

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Stress>Second Piola-Kirchhoff stress (material and geometry frames) - N/m²>solid.SYY - Second Piola-Kirchhoff stress, YY component.

|

|

4

|

|

5

|

Click to expand the Coloring and Style section. Find the Line markers subsection. From the Marker list, choose Cycle.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coloring and Style section. Find the Line markers subsection. In the Number text field, type 10.

|

|

5

|

Locate the Legends section. In the table, enter the following settings:

|

|

6

|

|

7

|