|

|

•

|

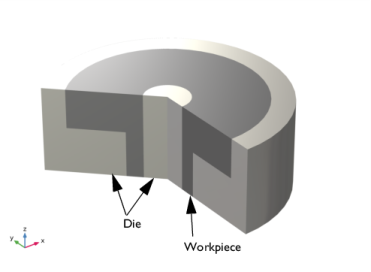

Since no physics is defined on the die, it is in the Contact node considered as external to the current physics.

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

In the Settings window for Interpolation, type Density in Isotropic Compression Test - Experiment in the Label text field.

|

|

4

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file compaction_of_a_rotational_flange_isotropiccompression_experiment.txt.

|

|

1

|

|

2

|

In the Settings window for Interpolation, type Density in Isotropic Compression Test - Simulation in the Label text field.

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file compaction_of_a_rotational_flange_isotropiccompression_simulation.txt.

|

|

1

|

|

2

|

In the Settings window for Interpolation, type Density in Triaxial Test - Experiment in the Label text field.

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file compaction_of_a_rotational_flange_triaxial_experiment1.txt.

|

|

1

|

|

2

|

In the Settings window for Interpolation, type Density in Triaxial Test - Simulation in the Label text field.

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file compaction_of_a_rotational_flange_triaxial_simulation1.txt.

|

|

1

|

|

2

|

In the Settings window for Interpolation, type Axial Stress in Triaxial Test - Experiment in the Label text field.

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file compaction_of_a_rotational_flange_triaxial_experiment2.txt.

|

|

1

|

|

2

|

In the Settings window for Interpolation, type Axial Stress in Triaxial Test - Simulation in the Label text field.

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file compaction_of_a_rotational_flange_triaxial_simulation2.txt.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Definitions click Density in Isotropic Compression Test - Experiment (int1).

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Definitions click Density in Isotropic Compression Test - Simulation (int2).

|

|

2

|

|

1

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Density vs. Hydrostatic Pressure in Isotropic Compression Test in the Label text field.

|

|

3

|

|

4

|

|

5

|

In the associated text field, type Hydrostatic Pressure (MPa).

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

In the Model Builder window, expand the Density vs. Hydrostatic Pressure in Isotropic Compression Test node, then click Function 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

Right-click Results>Density vs. Hydrostatic Pressure in Isotropic Compression Test>Function 1 and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Legends section. In the table, enter the following settings:

|

|

7

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Definitions click Density in Triaxial Test - Simulation (int4).

|

|

2

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Density vs. Logarithmic Axial Strain in Triaxial Test in the Label text field.

|

|

3

|

|

4

|

|

5

|

In the associated text field, type Logarithmic Axial Strain (1).

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

In the Model Builder window, expand the Density vs. Logarithmic Axial Strain in Triaxial Test node, then click Function 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

Right-click Results>Density vs. Logarithmic Axial Strain in Triaxial Test>Function 1 and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Legends section. In the table, enter the following settings:

|

|

7

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Definitions click Axial Stress in Triaxial Test - Simulation (int6).

|

|

2

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Axial Cauchy Stress vs. Logarithmic Axial Strain in Triaxial Test in the Label text field.

|

|

3

|

|

4

|

|

5

|

In the associated text field, type Logarithmic Axial Strain (1).

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

In the Model Builder window, expand the Axial Cauchy Stress vs. Logarithmic Axial Strain in Triaxial Test node, then click Function 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

Right-click Results>Axial Cauchy Stress vs. Logarithmic Axial Strain in Triaxial Test>Function 1 and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Legends section. In the table, enter the following settings:

|

|

7

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 right-click Rectangle 3 (r3) and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

On the object fin, select Boundary 8 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

Click to expand the Control Entities section. Clear the Smooth across removed control entities check box.

|

|

6

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

Click to expand the Control Entities section. Clear the Smooth across removed control entities check box.

|

|

6

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1 node, then click Parametric 1.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Strain>Strain invariants>solid.epvol - Volumetric plastic strain.

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Results>Datasets right-click Revolution 2D 1 and choose Duplicate.

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Results>Stress, 3D (solid) node, then click Stress, 3D (solid).

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Current Relative Density at Middle of Compaction in the Label text field.

|

|

3

|

|

1

|

In the Model Builder window, expand the Current Relative Density at Middle of Compaction node, then click Contour 1.

|

|

2

|

In the Settings window for Contour, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Porous plasticity>solid.lemm1.popl1.rhorel - Current relative density.

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, right-click Current Relative Density at Middle of Compaction and choose Duplicate.

|

|

2

|

In the Settings window for 2D Plot Group, type Current Relative Density at End of Compaction in the Label text field.

|

|

3

|

|

4

|