|

|

•

|

|

•

|

R is the gas constant (J/(mol·K))

|

|

•

|

T is temperature (K)

|

|

•

|

|

•

|

|

•

|

|

•

|

|

•

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

In the Select Physics tree, select Mathematics>PDE Interfaces>Lower Dimensions>General Form Boundary PDE (gb).

|

|

5

|

Click Add.

|

|

6

|

In the Dependent variables table, enter the following settings:

|

|

7

|

Click

|

|

8

|

|

9

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file transport_and_adsorption_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Transport of Diluted Species (tds) click Transport Properties 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

6

|

|

7

|

In the Dependent variable quantity table, enter the following settings:

|

|

8

|

In the Source term quantity table, enter the following settings:

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>General Form Boundary PDE (gb) click General Form PDE 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

In the associated text field, type 1.5[um].

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Settings window for 2D Plot Group, type Concentration species in reactor in the Label text field.

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Concentration reacting species along active surface in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

3

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the x-Axis Data section. From the menu, choose Component 1 (comp1)>Geometry>Coordinate>y - y-coordinate.

|

|

4

|

|

1

|

In the Model Builder window, right-click Concentration reacting species along active surface and choose Duplicate.

|

|

2

|

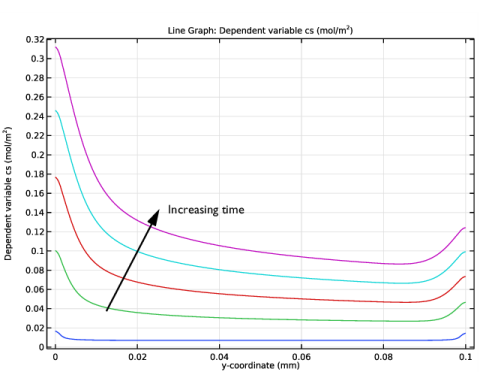

In the Settings window for 1D Plot Group, type Concentration adsorbed species along active surface in the Label text field.

|

|

3

|

|

1

|

In the Model Builder window, expand the Concentration adsorbed species along active surface node, then click Line Graph 1.

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>General Form Boundary PDE>cs - Dependent variable cs - mol/m².

|

|

3

|

|

1

|

In the Model Builder window, right-click Concentration adsorbed species along active surface and choose Duplicate.

|

|

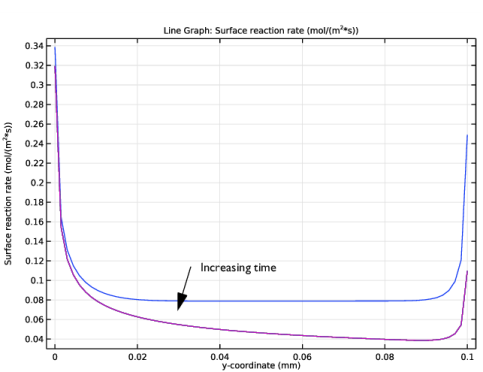

2

|

In the Settings window for 1D Plot Group, type Surface reaction rate along active surface in the Label text field.

|

|

1

|

In the Model Builder window, expand the Surface reaction rate along active surface node, then click Line Graph 1.

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>R - Surface reaction rate - mol/(m²·s).

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Concentration adsorbed species at active surface in the Label text field.

|

|

1

|

In the Model Builder window, expand the Concentration adsorbed species at active surface node, then click Line 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|