|

|

•

|

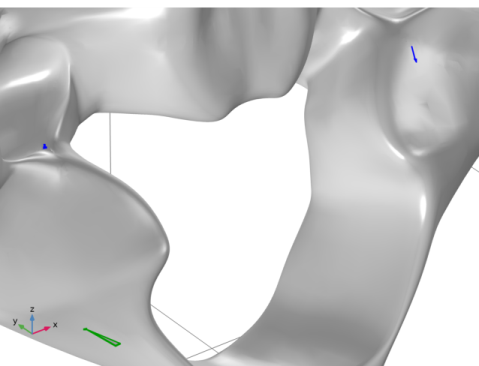

Using a Swept mesh operation to create a structured mesh.

|

|

1

|

|

2

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click Browse.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click the

|

|

9

|

Open up the Selection List from the Windows menu on the Home toolbar. If there are more than 3 edges listed in the Selection List, go back to the Import 1 node and make sure that the setting Boundary partitioning is set to Minimal, then reimport the mesh. Keep the Selection List open as you will use it later on.

|

|

11

|

|

12

|

Click the

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Go to the Selection List.

|

|

8

|

|

1

|

|

2

|

Go to the Model Builder window.

|

|

3

|

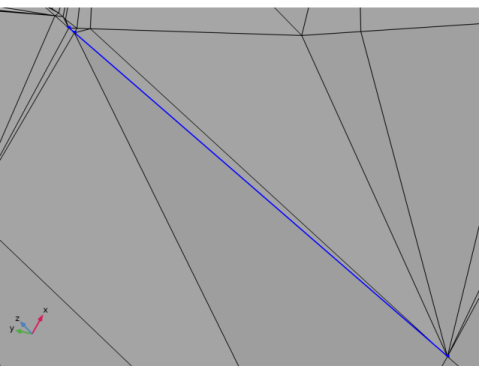

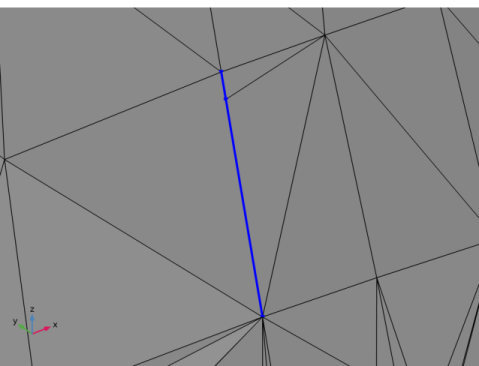

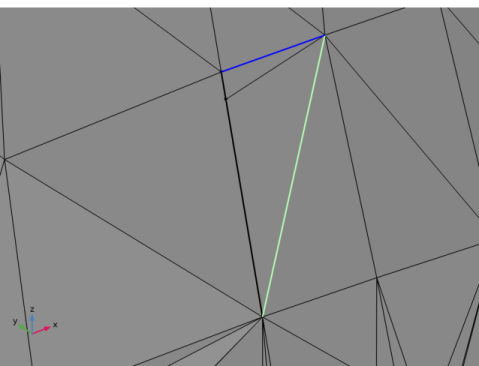

In the Graphics window, select element edges as in the image below (highlighted in blue and green) by clicking on the mesh edges with the mouse cursor.

|

|

4

|

|

1

|

|

3

|

|

1

|

|

3

|

|

4

|

Click the

|

|

5

|

|

7

|

|

8

|

|

9

|

In the Maximum hole perimeter text field, type 2.3[mm]. The value you enter here should be slightly larger than the measured hole perimeter.

|

|

10

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

1

|

|

1

|

In the Mesh toolbar, click

|

|

2

|

|

3

|

From the Source list, choose Meshing sequence. This will automatically suggest to import Mesh 2, which is the mesh of the block.

|

|

4

|

Click Import.

|

|

5

|

|

6

|

|

7

|

|

8

|

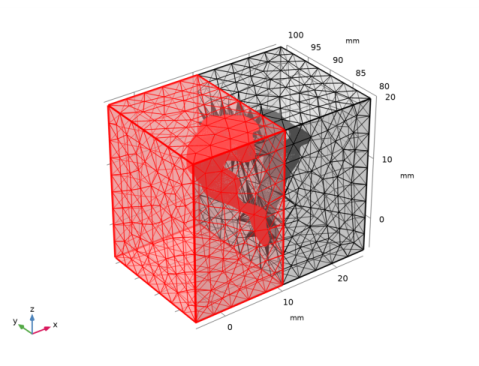

Rotate the mesh in the Graphics window to check that the vertebra is fully contained in the block, the two meshes should not intersect.

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Selection List window, choose 1 (meshed), 2 (meshed), 3 (meshed), 4 (meshed), 5 (meshed), and 6 (meshed) by pressing down the Ctrl key at the same time as clicking them in the list.

|

|

3

|

|

1

|

|

2

|

In the Settings window for Delete Entities, click

|

|

3

|

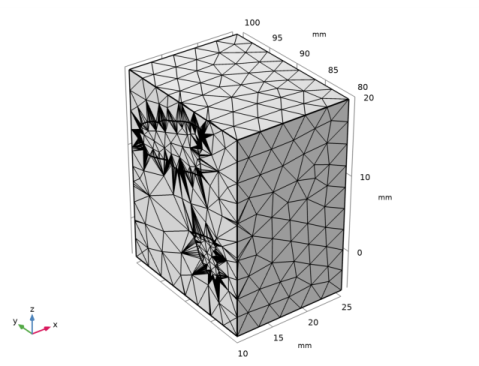

In the Selection list, confirm that we have the expected nine boundaries; six for the block and three for the vertebra. If there are more than 9 boundaries in the list, check the tolerance setting for the Intersect with plane operation.

|

|

4

|

Click the

|

|

1

|

|

3

|

|

4

|

In the Relative simplification tolerance text field, type 0.001. The lowered tolerance allows for a closer representation of the curved parts of the vertebra faces with smaller radius.

|

|

1

|

In the Model Builder window, right-click Free Triangular 1 and choose Size to set a finer mesh size on the face of the vertebra.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click the

|

|

9

|

|

1

|

|

2

|

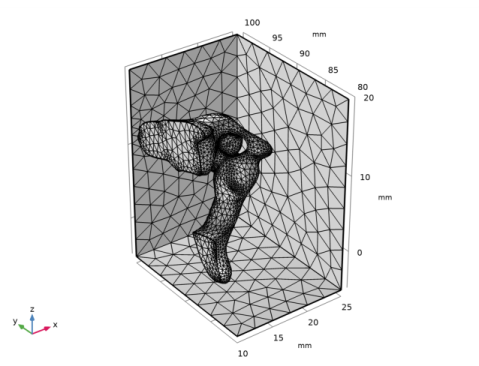

Check the Messages window. Two domains were created; one for the vertebra and one for the domain of the surrounding block.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|