|

|

•

|

|

•

|

ρ is the fluid’s density

|

|

•

|

Umean is the mean velocity

|

|

•

|

A is the projected area (product of thickness and diameter of cylinder)

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Select the object r1 only.

|

|

3

|

|

4

|

|

5

|

Select the object c1 only.

|

|

6

|

|

7

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Laminar Flow (spf) and choose Inlet.

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

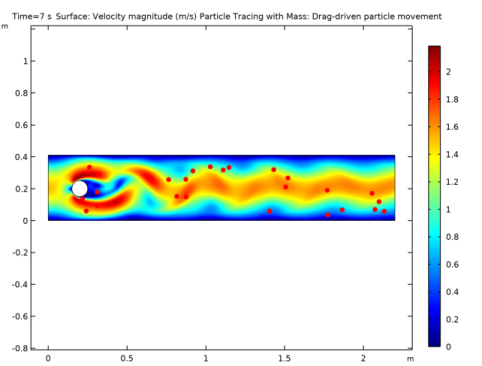

In the Settings window for Particle Tracing with Mass, click to expand the Mass and Velocity section.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

11

|

|

12

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Type list, choose None.

|

|

13

|

|

14

|

|

15

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Select the Description check box.

|

|

5

|

In the associated text field, type Lift coefficient.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Select the Description check box.

|

|

5

|

In the associated text field, type Drag coefficient.

|

|

6

|