|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

|

5

|

Click Add.

|

|

6

|

|

7

|

Click Add.

|

|

8

|

Click

|

|

9

|

|

10

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file microchannel_dispersion_optimization_geom_parameters.txt.

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file microchannel_dispersion_optimization_model_parameters.txt.

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select all objects.

|

|

1

|

|

2

|

Select the object ccur1 only.

|

|

1

|

|

2

|

Select the object csol1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Electric Currents (ec) and choose Ground.

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Transport of Diluted Species (tds) click Transport Properties 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

|

5

|

Click Replace.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Velocity and Electric Potential (Original Channel) in the Label text field.

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, right-click Velocity and Electric Potential (Original Channel) and choose Contour.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

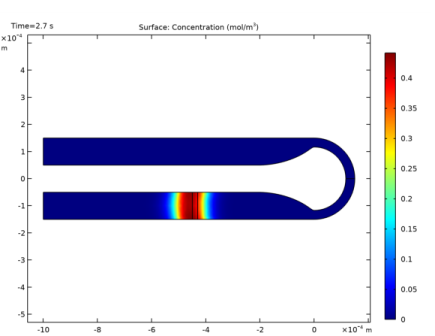

In the Settings window for 2D Plot Group, type Concentration (Original Channel) in the Label text field.

|

|

3

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Transport of Diluted Species>Species c>c - Concentration - mol/m³.

|

|

3

|

|

1

|

|

2

|

|

3

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Transport of Diluted Species (tds).

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

7

|

Click

|

|

9

|

Click

|

|

11

|

Click

|

|

13

|

Click

|

|

15

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Velocity and Electric Potential (Optimized Channel) in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Creeping Flow>Velocity and pressure>spf.U - Velocity magnitude - m/s.

|

|

1

|

In the Model Builder window, right-click Velocity and Electric Potential (Optimized Channel) and choose Contour.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check boxes for Electric Currents (ec) and Creeping Flow (spf).

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click to expand the Values of Dependent Variables section. Find the Initial values of variables solved for subsection. From the Settings list, choose User controlled.

|

|

7

|

|

8

|

|

9

|

Find the Values of variables not solved for subsection. From the Settings list, choose User controlled.

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

15

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Concentration (Optimized Channel) in the Label text field.

|

|

3

|

Locate the Data section. From the Dataset list, choose Optimized Channel Verification/Solution 6 (sol6).

|

|

4

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Transport of Diluted Species>Species c>c - Concentration - mol/m³.

|

|

3

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Average Concentration in Detector in the Label text field.

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|