|

|

•

|

mb is the mass of the balancing mass

|

|

•

|

mcl is the mass of the unbalanced clothes

|

|

•

|

rb is the radial position of the balancing mass

|

|

•

|

rcl is the radial position of the unbalanced clothes

|

|

•

|

ω is the angular velocity of the drum

|

|

•

|

φ0 is the initial angle of the balancing mass with horizontal axis

|

|

•

|

β is the relative rotation between the drum and the slot

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file washing_machine_walk_parameters.txt.

|

|

1

|

|

2

|

|

3

|

Click Browse.

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file washing_machine_walk.mphbin.

|

|

5

|

Click Import.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

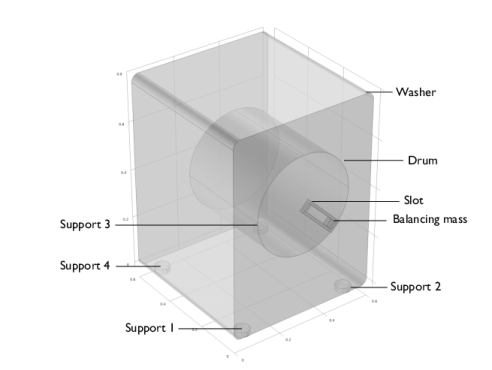

In the Model Builder window, under Component 1 (comp1) right-click Multibody Dynamics (mbd) and choose Rigid Domain.

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Rigid Domain: Drum node, then click Mass and Moment of Inertia 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Rigid Domain: Balancing mass node, then click Mass and Moment of Inertia 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

In the Model Builder window, expand the Planar Joint: Support 1 node, then click Center of Joint: Boundary 1.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, expand the Planar Joint: Support 2 node, then click Center of Joint: Boundary 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, expand the Planar Joint: Support 3 node, then click Center of Joint: Boundary 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, expand the Planar Joint: Support 4 node, then click Center of Joint: Boundary 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, expand the Hinge Joint: Washer-drum node, then click Center of Joint: Boundary 1.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Prismatic Joint, type Prismatic Joint: Slot-balancing mass in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, expand the Prismatic Joint: Slot-balancing mass node, then click Center of Joint: Boundary 1.

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file washing_machine_walk_variables.txt.

|

|

1

|

|

2

|

|

3

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click in the Graphics window and then press Ctrl+A to select all domains.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Results>Friction Force>Volume 1 node, then click Deformation 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

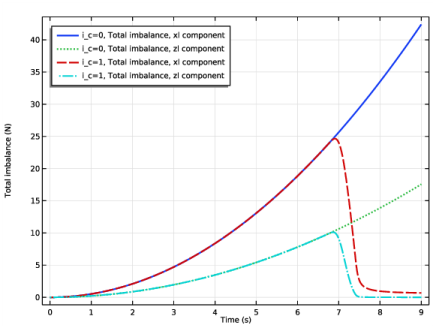

In the associated text field, type Total imbalance (N).

|

|

7

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>Fxl - Total imbalance, xl component - N.

|

|

3

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>Fzl - Total imbalance, zl component - N.

|

|

4

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose Cycle.

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>Fx - Total imbalance, x component - N.

|

|

3

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>Fz - Total imbalance, z component - N.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>Msl1 - Slip margin, support 1 - N.

|

|

3

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>Msl3 - Slip margin, support 3 - N.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>Msl_tot - Total slip margin - N.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Multibody Dynamics>Rigid domains>Rigid Domain: Washer>Rigid body rotation (spatial frame) - rad>mbd.rd1.thz - Rigid body rotation, z component.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the associated text field, type Angular velocity (rpm).

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>d_th - Correction angle - rad.

|

|

3

|

|

4

|

|

5

|

|

6

|