|

|

•

|

|

•

|

An external torque of 100 N-m is applied on the output shaft.

|

|

•

|

To build a gear geometry, you can import a gear part from the Parts Library and customize it by changing its input parameters. Alternatively, you can also create an equivalent disc or cone to represent the gear.

|

|

•

|

All the gears are assumed rigid. The elasticity of a gear mesh can be included on Gear Pair nodes using the Gear Elasticity subnode.

|

|

•

|

All the Gear Pair nodes are assumed ideal and frictionless. You can add Transmission Error, Backlash, or Friction subnodes when required.

|

|

•

|

To constraint the motion of a gear, you can use Prescribed Displacement/Rotation or Fixed Constraint subnodes. Alternatively, you can mount the gears on a shaft or on the ground through various Joint nodes.

|

|

•

|

The contact force on a Gear Pair is computed using Weak constraints or Penalty method. By default, the contact force computation is turned off. Use the weak constraints method for more accurate contact forces. However, you preferably opt for the penalty method for large rigid body systems.

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file gear_train_parameters.txt.

|

|

1

|

|

2

|

|

3

|

In the Part Libraries window, select Multibody Dynamics Module>2D>External Gears>spur_gear_2d in the tree.

|

|

4

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Destination Boundaries section. From the Selection list, choose Gear teeth, contact surface (Spur Gear (2D) 2).

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

|

1

|

|

2

|

|

1

|

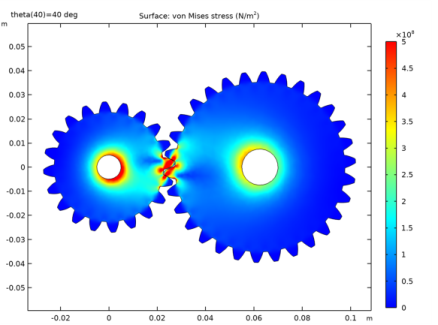

In the Model Builder window, expand the Displacement (mbd) 1 node, then click Results>von-Mises Stress>Surface.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

In the Settings window for Global Evaluation, click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Definitions>Variables>kg - Stiffness along the line of action - N/m.

|

|

3

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>kg - Stiffness along the line of action - N/m.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Click Browse.

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file gear_train.mphbin.

|

|

5

|

Click Import.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Study 1.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Find the Functions subsection. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

Specify the ω vector as

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Contact Force Computation section. From the list, choose Computed using weak constraints.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Line of Action section. From the Obtained by rotation of tangent in list, choose Counterclockwise direction.

|

|

6

|

|

7

|

Locate the Contact Force Computation section. From the list, choose Computed using weak constraints.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

Duplicate the Hinge Joint 1 to create more joints using the information given below:

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

From the list, choose Joint.

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Multibody Dynamics (mbd).

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Displacement-normal acceleration in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 2 (comp2)>Multibody Dynamics 2>Gear pairs>Gear Pair 1>mbd2.grp1.Fc - Force at contact point - N.

|

|

3

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 2 (comp2)>Multibody Dynamics 2>Gear pairs>Gear Pair 2>mbd2.grp2.Fc - Force at contact point - N.

|

|

4

|

|

5

|

|

6

|

Click Replace Expression in the upper-right corner of the x-Axis Data section. From the menu, choose Component 2 (comp2)>Multibody Dynamics 2>Hinge joints>Hinge Joint 1>mbd2.hgj1.th - Relative rotation - rad.

|

|

7

|

|

8

|

Select the Description check box.

|

|

9

|

In the associated text field, type Drive shaft rotation.

|

|

10

|

|

11

|

|

12

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

In the associated text field, type Angular velocity (rad/s).

|

|

5

|

|

1

|

In the Model Builder window, expand the Contact force 1 node, then click Results>Angular velocity>Global 1.

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 2 (comp2)>Multibody Dynamics 2>Hinge joints>Hinge Joint 1>mbd2.hgj1.th_t - Relative angular velocity - rad/s.

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Locate the Plot Settings section. In the y-axis label text field, type Angular acceleration (rad/s^2).

|

|

1

|

In the Model Builder window, expand the Angular velocity 1 node, then click Results>Angular acceleration>Global 1.

|

|

2

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

7

|

Select the Description check box.

|

|

8

|

In the associated text field, type Drive shaft rotation.

|

|

9

|

|

10

|

|

11

|

|

12

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Normal acceleration: frequency in the Label text field.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|