|

|

•

|

|

•

|

T (SI unit: K) is the temperature

|

|

•

|

|

•

|

Lv (SI unit: J/kg) is the latent heat of evaporation

|

|

•

|

δp (SI unit: s) is the vapor permeability

|

|

•

|

psat (SI unit: Pa) is the vapor saturation pressure

|

|

•

|

Q (SI unit: W/m3·s) is the heat source

|

|

•

|

ξ (SI unit: kg/m3) is the moisture storage capacity

|

|

•

|

|

•

|

G (SI unit: kg/m3·s) is the moisture source

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file wood_frame_wall_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

Select the object r2 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Heat Transfer in Building Materials (ht) click Building Material 1.

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Moisture Transport in Building Materials (mt) click Building Material 1.

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

1

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1)>Materials>Wooden panel (OSB) (mat5) node.

|

|

2

|

|

3

|

|

4

|

|

6

|

Locate the Interpolation and Extrapolation section. From the Interpolation list, choose Piecewise cubic.

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

5

|

Locate the Interpolation and Extrapolation section. From the Interpolation list, choose Piecewise cubic.

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Study, type Study 1 (Stationary, without vapor barrier) in the Label text field.

|

|

1

|

In the Model Builder window, under Study 1 (Stationary, without vapor barrier) click Step 1: Stationary.

|

|

2

|

|

3

|

|

4

|

In the Physics and variables selection tree, select Component 1 (comp1)>Moisture Transport in Building Materials (mt)>Thin Moisture Barrier 1.

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 1 (Stationary, without vapor barrier)>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1 node, then click Fully Coupled 1.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Settings window for Study, type Study 2 (Stationary, with vapor barrier) in the Label text field.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click

|

|

7

|

|

8

|

Click

|

|

1

|

|

2

|

In the Settings window for Cut Line 2D, type Cut Line Cellulose (solution 1) in the Label text field.

|

|

3

|

|

4

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 2 (Stationary, with vapor barrier)/Solution 2 (sol2).

|

|

4

|

Click

|

|

1

|

|

2

|

In the Settings window for Cut Line 2D, type Cut Line Cellulose (solution 2) in the Label text field.

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 2 (Stationary, with vapor barrier)/Solution 2 (sol2).

|

|

4

|

Click

|

|

1

|

|

2

|

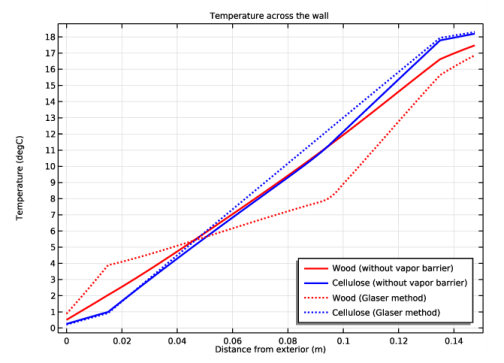

In the Settings window for 1D Plot Group, type Temperature across the wall (comparison) in the Label text field.

|

|

3

|

|

4

|

|

5

|

In the associated text field, type Distance from exterior (m).

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

10

|

|

11

|

|

1

|

|

2

|

In the Settings window for Line Graph, type Cellulose (without vapor barrier) in the Label text field.

|

|

3

|

|

4

|

|

5

|

Locate the Legends section. In the table, enter the following settings:

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dashed.

|

|

5

|

Locate the Legends section. In the table, enter the following settings:

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dashed.

|

|

5

|

Locate the Legends section. In the table, enter the following settings:

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

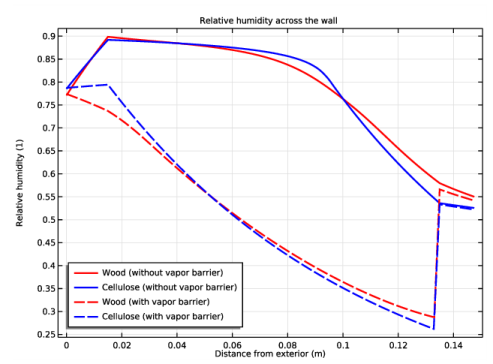

In the Settings window for 1D Plot Group, type Relative humidity across the wall (comparison) in the Label text field.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Heat Transfer in Building Materials 2 (ht2) click Building Material 1.

|

|

2

|

|

3

|

|

4

|

Locate the Building Material Properties section. From the δp list, choose User defined. In the associated text field, type 0.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Moisture Transport in Building Materials 2 (mt2) click Building Material 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Building Material section. From the Dw list, choose User defined. From the Specify list, choose Vapor resistance factor.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the table, clear the Solve for check boxes for Heat Transfer in Building Materials (ht) and Moisture Transport in Building Materials (mt).

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dotted.

|

|

5

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

In the Model Builder window, under Results>Temperature across the wall (comparison) click Cellulose (without vapor barrier) 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dotted.

|

|

6

|

Locate the Legends section. In the table, enter the following settings:

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dotted.

|

|

5

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

In the Model Builder window, under Results>Relative humidity across the wall (comparison) click Cellulose (without vapor barrier) 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dotted.

|

|

6

|

Locate the Legends section. In the table, enter the following settings:

|

|

7

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Definitions>Shared Properties click Ambient Properties 1 (ampr1).

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

Find the Date subsection. In the table, enter the following settings:

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Study, type Study 4 (Time dependent, with vapor barrier) in the Label text field.

|

|

1

|

In the Model Builder window, under Study 4 (Time dependent, with vapor barrier) click Step 1: Time Dependent.

|

|

2

|

|

3

|

In the table, clear the Solve for check boxes for Heat Transfer in Building Materials 2 (ht2) and Moisture Transport in Building Materials 2 (mt2).

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 4 (Time dependent, with vapor barrier)/Solution 4 (sol4).

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

In the Settings window for Domain Point Probe, type Domain Point Probe: Relative humidity (bracing) in the Label text field.

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Domain Point Probe: Relative humidity (bracing) node, then click Point Probe Expression 1 (ppb1).

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, right-click Domain Point Probe: Relative humidity (bracing) and choose Duplicate.

|

|

2

|

|

3

|

In the Settings window for Domain Point Probe, type Domain Point Probe: Relative humidity (isolation) in the Label text field.

|

|

4

|

|

1

|

|

2

|

In the Settings window for Point Probe Expression, click to expand the Table and Window Settings section.

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Relative humidity over two days in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|