|

|

•

|

|

•

|

k-ε equations in the fluid domain:

|

|

1

|

|

2

|

In the Select Physics tree, select Fluid Flow>Nonisothermal Flow>Turbulent Flow>Turbulent Flow, k-ε.

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

Select the object c1 only.

|

|

3

|

|

4

|

|

5

|

Select the object c2 only.

|

|

6

|

|

1

|

|

2

|

Select the object dif1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select all objects.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object uni1, select Domains 1, 2, 5, 7, 8, and 10 only.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

Click the Custom button.

|

|

3

|

|

5

|

|

1

|

|

1

|

|

2

|

Select the object del1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

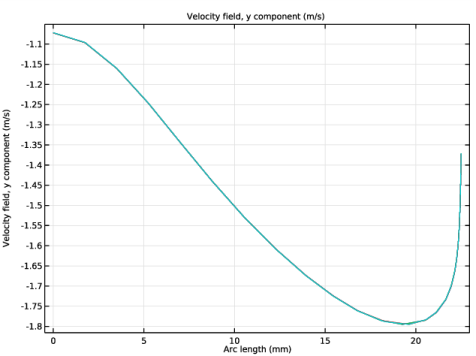

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Turbulent Flow, k-ε>Velocity and pressure>Velocity field - m/s>v - Velocity field, y component.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Turbulent Flow, k-ε>Velocity and pressure>p - Pressure - Pa.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Locate the Coloring and Style section. Find the Point style subsection. From the Type list, choose Arrow.

|

|

8

|

|

10

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Temperature along Arc Length in the Label text field.

|

|

3

|

|

1

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Heat Transfer in Fluids>Temperature>T - Temperature - K.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

Right-click and choose Duplicate.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Coloring and Style section. Find the Line style subsection. From the Type list, choose Tube.

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|