|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Select the object blk1 only.

|

|

3

|

|

4

|

|

5

|

Select the object blk2 only.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Select the object blk3 only.

|

|

3

|

|

4

|

|

5

|

Select the object dif1 only.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

Select the object blk3 only.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

Select the object dif2 only.

|

|

3

|

|

4

|

|

5

|

Select the object blk4 only.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

In the tree, select Built-in>Air.

|

|

4

|

|

5

|

In the tree, select Built-in>Alumina.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Heat Transfer in Solids and Fluids (ht) click Fluid 1.

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Mesh 1 and choose Edit Physics-Induced Sequence.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

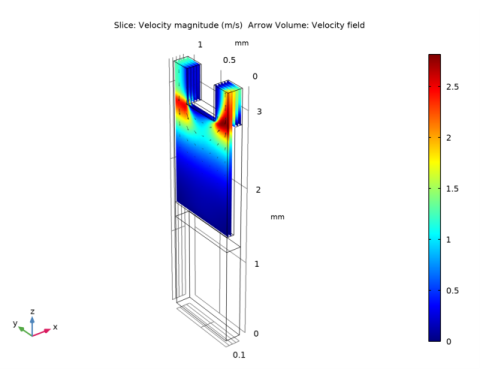

2

|

In the Settings window for Arrow Volume, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Laminar Flow>Velocity and pressure>u,v,w - Velocity field.

|

|

3

|

Locate the Arrow Positioning section. Find the x grid points subsection. In the Points text field, type 5.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for Surface Average, type Temperature Jump and Joint Conductance in the Label text field.

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

In the associated text field, type Upside temperature.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

In the associated text field, type Downside temperature.

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Results>Temperature (ht), Ctrl-click to select Surface 1, Surface 2, and Surface 3.

|

|

2

|

Right-click and choose Delete.

|

|

1

|

|

2

|

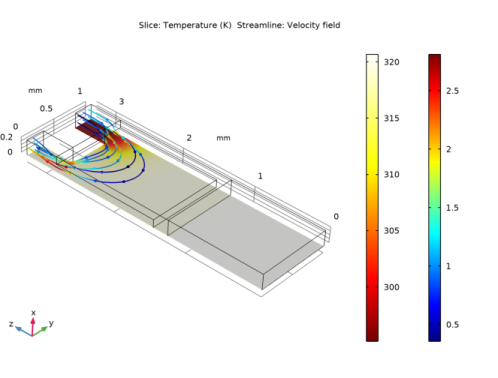

In the Settings window for Slice, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Heat Transfer in Solids and Fluids>Temperature>T - Temperature - K.

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Streamline, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Laminar Flow>Velocity and pressure>u,v,w - Velocity field.

|

|

4

|

|

5

|

Locate the Coloring and Style section. Find the Line style subsection. From the Type list, choose Tube.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

In the Settings window for Color Expression, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Laminar Flow>Velocity and pressure>spf.U - Velocity magnitude - m/s.

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1)>Definitions>View 1 node, then click Camera.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

15

|

|

16

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|