|

|

1

|

|

2

|

In the Select Physics tree, select Fluid Flow>Single-Phase Flow>Turbulent Flow>Turbulent Flow, Low Re k-ε (spf).

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Stationary with Initialization.

|

|

6

|

Click

|

|

1

|

|

2

|

Browse to the model’s Application Libraries folder and double-click the file evaporative_cooling_geom_sequence.mph.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

In the tree, select Built-in>Air.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

6

|

|

7

|

|

8

|

Click OK.

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Click the Custom button.

|

|

5

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Boundary Layers 1 node, then click Boundary Layer Properties 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Study 1.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

1

|

|

1

|

|

2

|

In the Settings window for Convectively Enhanced Conductivity, locate the Convectively Enhanced Conductivity section.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

1

|

|

2

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Moisture Transport in Air (mt) click Initial Values 1.

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Multiphysics click Heat and Moisture 1 (ham1).

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

In the Settings window for Wall Distance Initialization, locate the Physics and Variables Selection section.

|

|

3

|

In the table, clear the Solve for check boxes for Nonisothermal Flow 1 (nitf1) and Moisture Flow 1 (mf1).

|

|

1

|

|

2

|

|

3

|

In the table, clear the Solve for check boxes for Nonisothermal Flow 1 (nitf1) and Moisture Flow 1 (mf1).

|

|

1

|

|

2

|

|

3

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Turbulent Flow, Low Re k-ε (spf).

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click to expand the Values of Dependent Variables section. Find the Values of variables not solved for subsection. From the Settings list, choose User controlled.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Coloring and Style section. Find the Point style subsection. From the Color list, choose White.

|

|

6

|

Locate the Streamline Positioning section. From the Positioning list, choose On selected boundaries.

|

|

7

|

|

9

|

|

10

|

|

12

|

|

13

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Data section. From the Dataset list, choose Study 2 : no latent heat source/Solution 3 (sol3).

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Moisture Concentration and Relative Humidity in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Moisture Transport in Air>mt.cv - Vapor concentration - mol/m³.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 2 : no latent heat source/Solution 3 (sol3).

|

|

5

|

Click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Heat Transfer in Moist Air>Temperature>T - Temperature - K.

|

|

6

|

Locate the Expressions section. In the table, enter the following settings:

|

|

7

|

Click

|

|

1

|

Go to the Table window.

|

|

2

|

|

1

|

|

2

|

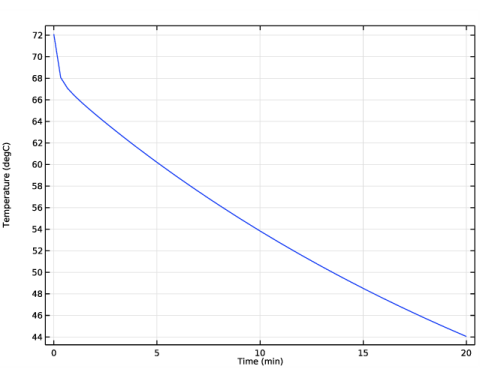

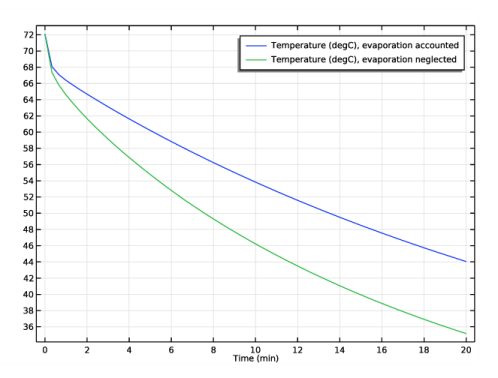

In the Settings window for 1D Plot Group, type Average Water Temperature over Time in the Label text field.

|

|

1

|

|

2

|

In the Settings window for Surface Integration, type Amount of Evaporated Water in the Label text field.

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 2 : no latent heat source/Solution 3 (sol3).

|

|

5

|

Locate the Expressions section. In the table, enter the following settings:

|

|

6

|

|

7

|

|

1

|

Go to the Table window.

|

|

1

|

|

1

|

|

1

|

|

2

|

In the Settings window for Wall Distance Initialization, locate the Physics and Variables Selection section.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Turbulent Flow, Low Re k-ε (spf).

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Values of Dependent Variables section. Find the Values of variables not solved for subsection. From the Settings list, choose User controlled.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

1

|

Go to the Table window.

|

|

2

|

|

1

|

In the Model Builder window, expand the Results>Tables node, then click Results>Average Water Temperature over Time>Table Graph 1.

|

|

2

|

|

3

|

|

4

|

|

6

|