|

|

ρ (kg/m3)

|

|||

|

Cp (J/(kg·K))

|

|||

|

k (W/(m·K))

|

|||

|

μ (Ns/m2)

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file continuous_casting_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Browse to the model’s Application Libraries folder and double-click the file continuous_casting_variables.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

7

|

|

8

|

|

1

|

|

2

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Specify the u vector as

|

|

1

|

|

3

|

|

4

|

From the list, choose Pressure.

|

|

1

|

|

3

|

|

4

|

From the list, choose Velocity.

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

1

|

|

3

|

In the Settings window for Surface-to-Ambient Radiation, locate the Surface-to-Ambient Radiation section.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

Click Yes to confirm.

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1)>Meshes node, then click Level 2 Adapted Mesh 2.

|

|

2

|

|

3

|

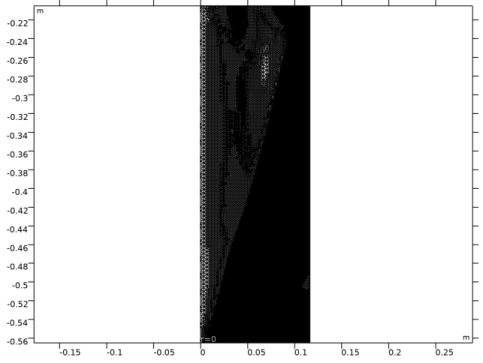

Click the Zoom Box button in the Graphics toolbar and then use the mouse to zoom in on the transition zone where the mesh is the densest.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Find the Initial values of variables solved for subsection. From the Settings list, choose User controlled.

|

|

4

|

|

5

|

|

6

|

|

7

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Coloring and Style section. Find the Point style subsection. From the Type list, choose Arrow.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Definitions>Variables>alpha - Fraction of liquid phase.

|

|

3

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Temperature, Velocity Fields in the Label text field.

|

|

3

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Heat Transfer in Fluids>Temperature>T - Temperature - K.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Coloring and Style section. Find the Point style subsection. From the Type list, choose Arrow.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Heat Transfer in Fluids>Domain fluxes>ht.dfluxMag - Conductive heat flux magnitude - W/m².

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Coloring and Style section. Find the Point style subsection. From the Type list, choose Arrow.

|

|

6

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Conductive Heat Flux through Outer Boundaries in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

In the associated text field, type z-coordinate (m).

|

|

9

|

|

10

|

In the associated text field, type Normal conductive heat flux (W/m^2).

|

|

1

|

|

3

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Heat Transfer in Fluids>Boundary fluxes>ht.ndflux - Normal conductive heat flux - W/m².

|

|

4

|

Click Replace Expression in the upper-right corner of the x-Axis Data section. From the menu, choose Component 1 (comp1)>Geometry>Coordinate>z - z-coordinate.

|

|

5

|

Click to expand the Legends section. Click to collapse the Legends section. Click to expand the Quality section. From the Recover list, choose Within domains.

|

|

6

|

Click to collapse the Quality section. In the Conductive Heat Flux through Outer Boundaries toolbar, click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Temperature Dependence, Latent Heat in the Label text field.

|

|

3

|

|

1

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>D - Temperature dependence, latent heat - 1/K.

|

|

3

|

|

4

|