|

|

•

|

|

•

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Clear the Bottom check box.

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

Select the object blk2 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

In the tree, select Built-in>Air.

|

|

4

|

|

5

|

In the tree, select Built-in>Silicon.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

1

|

In the Model Builder window, under Component 1 (comp1) click Heat Transfer in Solids and Fluids (ht).

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Heat Transfer in Solids and Fluids (ht) click Fluid 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

Click Yes to confirm.

|

|

1

|

|

2

|

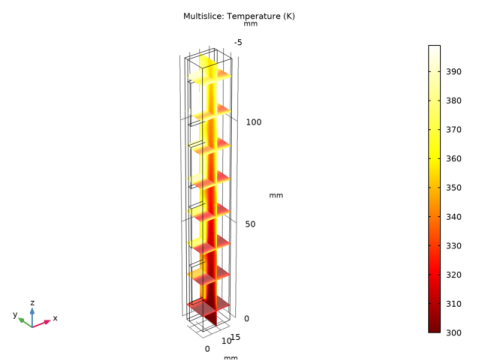

In the Settings window for Multislice, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Heat Transfer in Solids and Fluids>Temperature>T - Temperature - K.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

Click Yes to confirm.

|

|

1

|

|

2

|

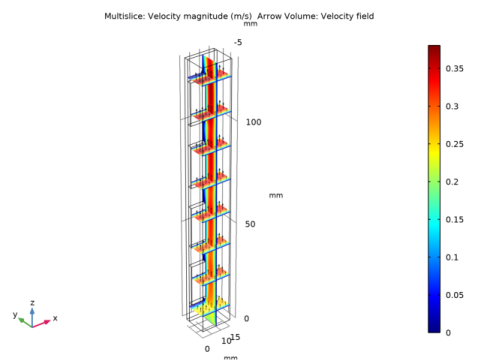

In the Settings window for Multislice, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Laminar Flow>Velocity and pressure>spf.U - Velocity magnitude - m/s.

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Arrow Volume, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Laminar Flow>Velocity and pressure>u,v,w - Velocity field.

|

|

3

|

Locate the Arrow Positioning section. Find the x grid points subsection. In the Points text field, type 5.

|

|

4

|

|

5

|

|

6

|

|

7

|