|

|

1

|

|

2

|

In the Select Physics tree, select Heat Transfer>Radiation>Heat Transfer with Surface-to-Surface Radiation.

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Heat Transfer in Solids (ht) click Initial Values 1.

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Surface-to-Surface Radiation (rad) click Diffuse Surface 1.

|

|

2

|

|

3

|

|

4

|

Locate the Surface Emissivity section. From the ε list, choose User defined. In the associated text field, type 0.8.

|

|

1

|

|

3

|

|

4

|

|

5

|

Locate the Surface Emissivity section. From the ε list, choose User defined. In the associated text field, type 0.4.

|

|

1

|

|

3

|

|

4

|

|

5

|

Locate the Surface Emissivity section. From the ε list, choose User defined. In the associated text field, type 0.6.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

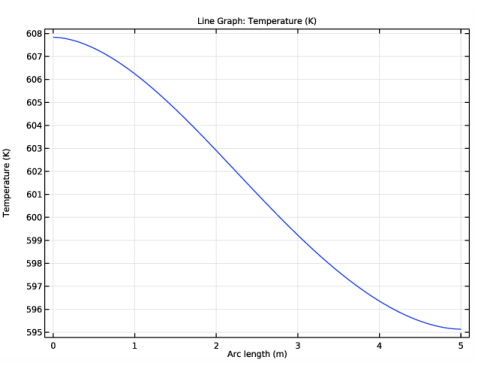

In the Settings window for 1D Plot Group, type Temperature Profile vs. Arc Length in the Label text field.

|

|

1

|

|

3

|

|

1

|

|

2

|

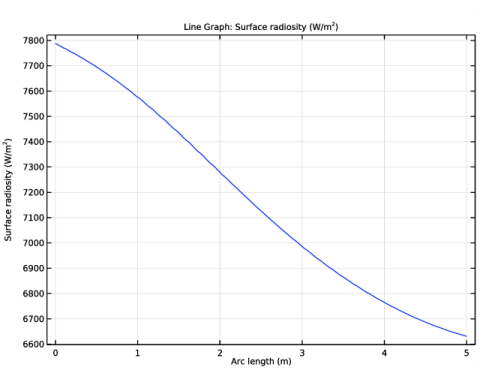

In the Settings window for 1D Plot Group, type Surface Radiosity Profile vs. Arc Length in the Label text field.

|

|

1

|

In the Model Builder window, expand the Surface Radiosity Profile vs. Arc Length node, then click Line Graph 1.

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Surface-to-Surface Radiation>Surface radiosity>rad.J - Surface radiosity - W/m².

|

|

3

|

|

1

|

|

3

|

In the Settings window for Line Integration, click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Heat Transfer in Solids>Boundary fluxes>ht.ndflux - Normal conductive heat flux - W/m².

|

|

4

|

Click

|

|

1

|

Go to the Table window.

|

|

1

|

|

3

|

|

5

|

Click

|

|

1

|

Go to the Table window.

|

|

1

|

|

3

|

|

5

|

Click

|

|

1

|

Go to the Table window.

|