|

|

104

|

||

|

•

|

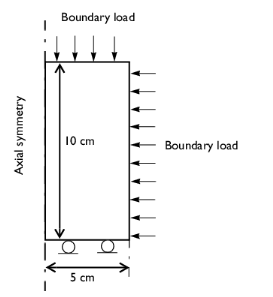

The boundary load is applied in three steps: First the pressure increases from 0.5p0 to 3p0, then the sample is unloaded until the pressure reaches 1.5p0, and finally the pressure increases again until it reaches 4p0.

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Definition section. In the table, enter the following settings:

|

|

6

|

|

7

|

|

8

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Solid Mechanics (solid) and choose Material Models>Elastoplastic Soil Material.

|

|

2

|

In the Settings window for Elastoplastic Soil Material, type Modified Cam-Clay Model (MCC) in the Label text field.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

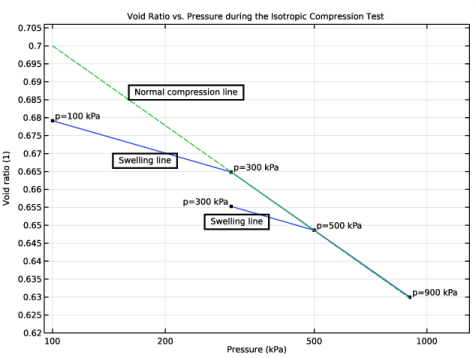

In the associated text field, type Pressure (kPa).

|

|

7

|

|

8

|

In the associated text field, type Void ratio (1).

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

15

|

|

1

|

|

3

|

In the Settings window for Point Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Soil material properties>Modified Cam-Clay>solid.epsm1.evoid - Void ratio.

|

|

4

|

Click Replace Expression in the upper-right corner of the x-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Stress>solid.pm - Pressure - N/m².

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Results>Void Ratio (MCC) right-click Point Graph 1 and choose Duplicate.

|

|

2

|

|

3

|

In the Expression text field, type solid.epsm1.evoidref-solid.epsm1.lambdaComp*log(solid.epsm1.p/solid.epsm1.pref).

|

|

4

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dashed.

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Void Ratio (MCC), Numerical Vs. Analytical in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

In the associated text field, type Pressure (kPa).

|

|

7

|

|

8

|

In the associated text field, type Void ratio (1).

|

|

9

|

|

1

|

|

3

|

In the Settings window for Point Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Soil material properties>Modified Cam-Clay>solid.epsm1.evoid - Void ratio.

|

|

4

|

Click Replace Expression in the upper-right corner of the x-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Stress>solid.pm - Pressure - N/m².

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

In the Expression text field, type solid.epsm1.evoidref-(solid.epsm1.lambdaComp-solid.epsm1.kappaSwelling)*log(solid.epsm1.pc/solid.epsm1.pref)-solid.epsm1.kappaSwelling*log(solid.epsm1.p/solid.epsm1.pref).

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dashed.

|

|

5

|

Locate the Legends section. In the table, enter the following settings:

|

|

6

|

|

1

|

|

2

|

In the Settings window for Elastoplastic Soil Material, type Extended Barcelona Basic Model (BBMx) in the Label text field.

|

|

3

|

Locate the Elastoplastic Soil Material section. From the Material model list, choose Extended Barcelona Basic.

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Physics and variables selection tree, select Component 1 (comp1)>Solid Mechanics (solid)>Extended Barcelona Basic Model (BBMx).

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Physics and variables selection tree, select Component 1 (comp1)>Solid Mechanics (solid)>Modified Cam-Clay Model (MCC).

|

|

5

|

Click

|

|

6

|

|

7

|

Click

|

|

9

|

|

1

|

|

2

|

In the Settings window for Elastoplastic Soil Material, type Modified Structured Cam-Clay Model (MSCC) in the Label text field.

|

|

3

|

Locate the Elastoplastic Soil Material section. From the Material model list, choose Modified Structured Cam-Clay.

|

|

4

|

|

5

|

From the pbi list, choose User defined. From the ζ list, choose User defined. In the associated text field, type 2.

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

In the Physics and variables selection tree, select Component 1 (comp1)>Solid Mechanics (solid)>Modified Structured Cam-Clay Model (MSCC).

|

|

4

|

Click

|

|

1

|

|

2

|

|

3

|

In the Physics and variables selection tree, select Component 1 (comp1)>Solid Mechanics (solid)>Modified Structured Cam-Clay Model (MSCC).

|

|

4

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Physics and variables selection tree, select Component 1 (comp1)>Solid Mechanics (solid)>Modified Cam-Clay Model (MCC) and Component 1 (comp1)>Solid Mechanics (solid)>Extended Barcelona Basic Model (BBMx).

|

|

5

|

Click

|

|

6

|

|

7

|

Click

|

|

9

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Void Ratio, MCC vs. BBMx vs. MSCC in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

In the associated text field, type Pressure (kPa).

|

|

7

|

|

8

|

In the associated text field, type Void ratio (1).

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

5

|

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Soil material properties>Modified Cam-Clay>solid.epsm1.evoid - Void ratio.

|

|

6

|

Click Replace Expression in the upper-right corner of the x-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Stress>solid.pm - Pressure - N/m².

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

5

|

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Soil material properties>Extended Barcelona Basic>solid.epsm2.evoid - Void ratio.

|

|

6

|

Click Replace Expression in the upper-right corner of the x-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Stress>solid.pm - Pressure - N/m².

|

|

7

|

|

8

|

Click to collapse the Coloring and Style section. Click to expand the Coloring and Style section. From the Color list, choose Green.

|

|

9

|

|

10

|

|

11

|

|

12

|

|

1

|

|

2

|

|

3

|

|

5

|

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Soil material properties>Modified Structured Cam-Clay>solid.epsm3.evoid - Void ratio.

|

|

6

|

Click Replace Expression in the upper-right corner of the x-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Stress>solid.pm - Pressure - N/m².

|

|

7

|

|

8

|

Click to collapse the Coloring and Style section. Click to expand the Coloring and Style section. From the Color list, choose Blue.

|

|

9

|

|

10

|

|

11

|

|

12

|

|

14

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Consolidation Pressure vs. Boundary Load in the Label text field.

|

|

3

|

|

4

|

In the Title text area, type Consolidation Pressure vs. Boundary Load during the Isotropic Compression Test.

|

|

5

|

|

6

|

In the associated text field, type Boundary Load (kPa).

|

|

7

|

|

8

|

In the associated text field, type Consolidation Pressure (kPa).

|

|

1

|

|

2

|

|

3

|

|

5

|

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Soil material properties>Modified Cam-Clay>solid.epsm1.pc - Consolidation pressure - Pa.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

1

|

In the Model Builder window, right-click Consolidation Pressure vs. Boundary Load and choose Point Graph.

|

|

2

|

|

3

|

|

5

|

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Soil material properties>Extended Barcelona Basic>solid.epsm2.pcs - Consolidation pressure at current suction - Pa.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

1

|

|

2

|

|

3

|

|

5

|

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Soil material properties>Modified Structured Cam-Clay>solid.epsm3.pc - Consolidation pressure - Pa.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

In the Settings window for Point Evaluation, click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Soil material properties>Modified Cam-Clay>solid.epsm1.evoid - Void ratio.

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Expressions section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|