|

|

1

|

|

2

|

In the Select Physics tree, select Fluid Flow>Multiphase Flow>Mixture Model>Mixture Model, Laminar Flow (mm).

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

Browse to the model’s Application Libraries folder and double-click the file pem_electrolyzer_geom_sequence.mph.

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file pem_electrolyzer_parameters.txt.

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file pem_electrolyzer_variables.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

Select the Cutoff check box.

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Mixture Model, Laminar Flow (mm) click Mixture Properties 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Dispersed Phase Properties section. From the ρd list, choose User defined. In the associated text field, type rhoO2.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Inlet, type Inlet - Electrode Surface Oxygen Evolution in the Label text field.

|

|

3

|

|

4

|

|

5

|

Locate the Dispersed Phase Boundary Condition section. From the Dispersed phase boundary condition list, choose Dispersed phase flux.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click to expand the Source Faces section. From the Selection list, choose Inlets to Electrode Channels .

|

|

6

|

Click to expand the Destination Faces section. From the Selection list, choose Outlets from Electrode Channels.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

Locate the Geometric Entity Selection section. From the Geometric entity level list, choose Boundary.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 1 node, then click Volume fraction, dispersed phase (comp1.phid).

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 2 node, then click Volume fraction, dispersed phase (comp1.phid).

|

|

12

|

|

13

|

|

14

|

|

15

|

|

16

|

|

17

|

|

18

|

|

19

|

|

20

|

|

21

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Mixture Model, Laminar Flow>VelAndPressure>p - Pressure - Pa.

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

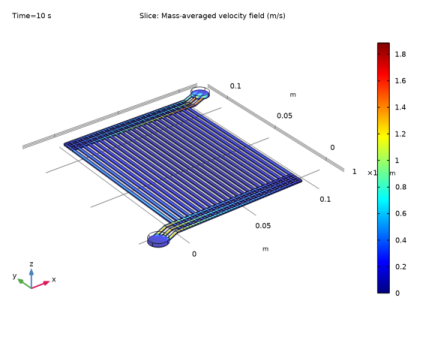

In the Settings window for Slice, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Mixture Model, Laminar Flow>VelAndPressure>mm.U - Mass-averaged velocity field - m/s.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

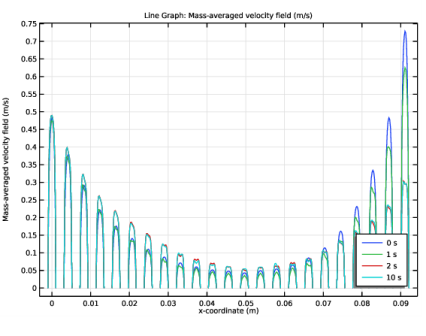

In the Settings window for 1D Plot Group, type Velocity in Electrode Channels in the Label text field.

|

|

3

|

|

1

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Mixture Model, Laminar Flow>VelAndPressure>mm.U - Mass-averaged velocity field - m/s.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Study 1>Solver Configurations right-click Solution 1 (sol1) and choose Solution>Copy.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 1 node, then click Volume fraction, dispersed phase (comp1.phid).

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 2 node, then click Volume fraction, dispersed phase (comp1.phid).

|

|

11

|

|

12

|

|

13

|

|

14

|

|

15

|

|

16

|

|

1

|

|

2

|

|

3

|

Select the Plot check box.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file pem_electrolyzer_geom_sequence_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

Select the object arr1(1,3,1) only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Select the object pol2 only.

|

|

6

|

|

1

|

|

2

|

Select the object dif1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select both objects.

|

|

3

|

|

1

|

|

2

|

Select the object uni1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

Select the object r3 only.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Select the object r4 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Select the object mov1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

Click in the Graphics window and then press Ctrl+A to select all objects.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

Right-click Component 1 (comp1)>Geometry 1>Work Plane 1 (wp1)>Plane Geometry>Fillet 1 (fil1) and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

Select the object cyl1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

Select the object rot1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Select the object mov1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Box Selection, type Channels Above Electrode Surface in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

In the Settings window for Adjacent Selection, type Exterior Boundaries to Electrode Channels in the Label text field.

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

In the Settings window for Adjacent Selection, type Exteror Boundaries to Inlet Manifold in the Label text field.

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

In the Settings window for Intersection Selection, type Inlets to Electrode Channels in the Label text field.

|

|

3

|

|

4

|

|

5

|

In the Add dialog box, in the Selections to intersect list, choose Exterior Boundaries to Electrode Channels and Exteror Boundaries to Inlet Manifold.

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

In the Settings window for Adjacent Selection, type Exterior Boundaries to Manifolds in the Label text field.

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

In the Settings window for Intersection Selection, type Inlets and Outlets to Electrode Channels in the Label text field.

|

|

3

|

|

4

|

|

5

|

In the Add dialog box, in the Selections to intersect list, choose Exterior Boundaries to Electrode Channels and Exterior Boundaries to Manifolds.

|

|

6

|

Click OK.

|

|

1

|

|

2

|

In the Settings window for Union Selection, type Electrode Channels and Manifolds in the Label text field.

|

|

3

|

|

4

|

In the Add dialog box, in the Selections to add list, choose Inlet Manifold, Outlet Manifold, and Channels Above Electrode Surface.

|

|

5

|

Click OK.

|

|

1

|

|

2

|

In the Settings window for Adjacent Selection, type Exteror Boundaries to Outlet Manifold in the Label text field.

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

In the Settings window for Intersection Selection, type Outlets from Electrode Channels in the Label text field.

|

|

3

|

|

4

|

|

5

|

In the Add dialog box, in the Selections to intersect list, choose Exterior Boundaries to Electrode Channels and Exteror Boundaries to Outlet Manifold.

|

|

6

|

Click OK.

|