|

|

HCOO-

|

||

|

OH-

|

||

|

L-2

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

|

5

|

In the Concentrations table, enter the following settings:

|

|

6

|

Click

|

|

7

|

|

8

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file cu_electroless_deposition_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

3

|

In the Settings window for Electrode Surface, click to expand the Dissolving-Depositing Species section.

|

|

4

|

Click

|

|

6

|

Locate the Electrode Phase Potential Condition section. From the Electrode phase potential condition list, choose Total current.

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

In the Stoichiometric coefficients for dissolving-depositing species: table, enter the following settings:

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Equilibrium Potential section. From the Eeq list, choose User defined. In the associated text field, type Eeq0_HCHO.

|

|

6

|

Locate the Electrode Kinetics section. From the Kinetics expression type list, choose Anodic Tafel equation.

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

3

|

|

4

|

|

5

|

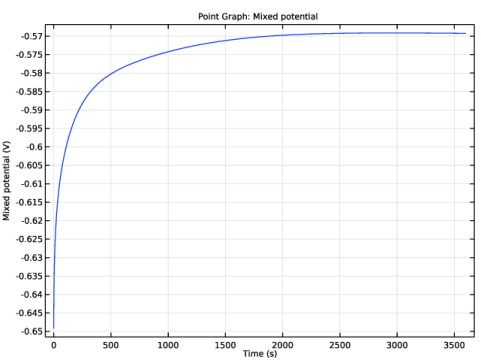

Select the Description check box.

|

|

6

|

In the associated text field, type Mixed potential.

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

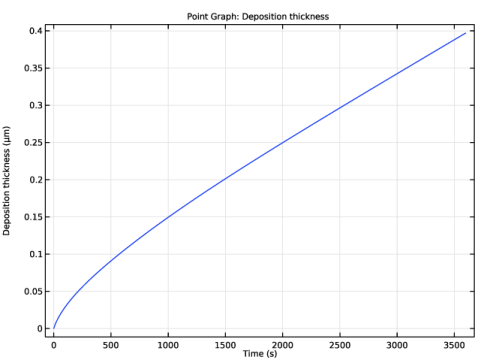

In the Settings window for Point Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Electroanalysis>Dissolving-depositing species>tcd.sbtot - Total electrode thickness change - m.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

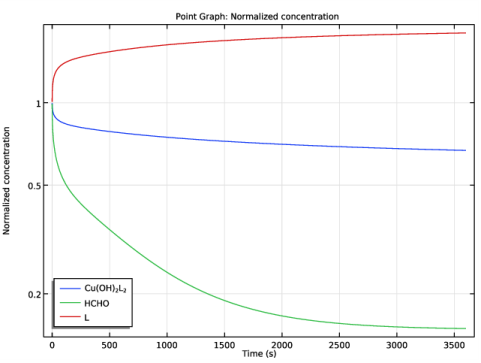

In the associated text field, type Normalized concentration.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

5

|

|

1

|

|

2

|

|

3

|