|

|

1

|

|

2

|

In the Select Physics tree, select Electrochemistry>Primary and Secondary Current Distribution>Secondary Current Distribution (cd).

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file al_anodization_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

Select the object r1 only.

|

|

3

|

|

4

|

|

5

|

Select the object r2 only.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

Select the object fil1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

4

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. Click New.

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

Select the object blk1 only.

|

|

3

|

|

4

|

|

5

|

Select the object mov1 only.

|

|

6

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Secondary Current Distribution (cd) click Electrolyte 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Browse.

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file al_polarization_data.csv.

|

|

6

|

Click Import.

|

|

7

|

Find the Functions subsection. In the table, enter the following settings:

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Electrode Phase Potential Condition section. From the Electrode phase potential condition list, choose Average current density.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

From the iloc,expr list, choose User defined. In the associated text field, type iloc_Al(cd.Evsref,T).

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Mesh 1 and choose Edit Physics-Induced Sequence.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

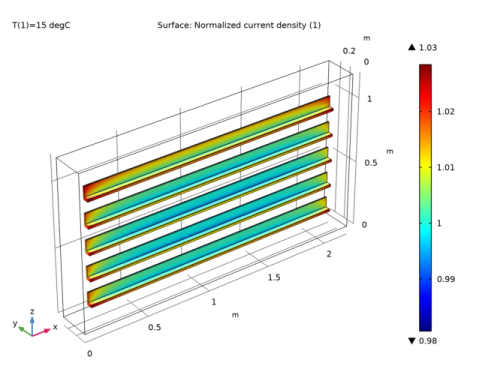

In the Settings window for 3D Plot Group, type Normalized Current Distribution in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Select the Description check box.

|

|

5

|

In the associated text field, type Normalized current density.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Deposited Layer Thickness after 25 min in the Label text field.

|

|

1

|

In the Model Builder window, expand the Deposited Layer Thickness after 25 min node, then click Surface 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|