|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

In the Select Physics tree, select Electrochemistry>Primary and Secondary Current Distribution>Secondary Current Distribution (cd).

|

|

5

|

Click Add.

|

|

6

|

Click

|

|

7

|

|

8

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Select the object r1 only.

|

|

3

|

|

4

|

|

5

|

Select the object e1 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file stress_corrosion_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file stress_corrosion_variables.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file stress_corrosion_stress_strain_curve_interpolation.txt.

|

|

6

|

Locate the Interpolation and Extrapolation section. From the Interpolation list, choose Piecewise cubic.

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Solid Mechanics (solid) click Initial Values 1.

|

|

2

|

|

3

|

Specify the u vector as

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Secondary Current Distribution (cd) click Electrolyte 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Electrode Kinetics section. From the Kinetics expression type list, choose Anodic Tafel equation.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Electrode Kinetics section. From the Kinetics expression type list, choose Cathodic Tafel equation.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

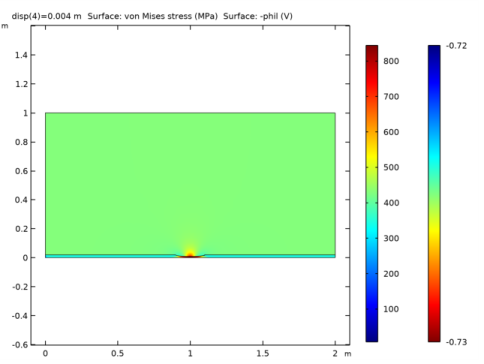

In the Settings window for 2D Plot Group, type Corrosion potential and von Mises stress in the Label text field.

|

|

3

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Stress>solid.mises - von Mises stress - N/m².

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

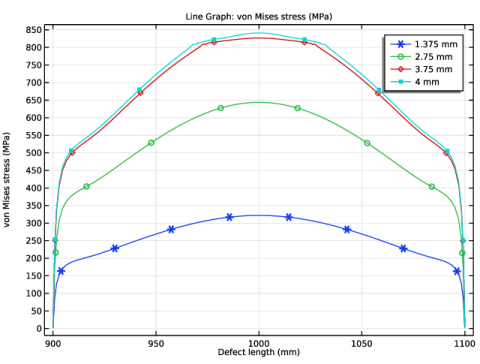

In the associated text field, type Defect length (mm).

|

|

1

|

|

3

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Stress>solid.mises - von Mises stress - N/m².

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click to expand the Coloring and Style section. Find the Line markers subsection. From the Marker list, choose Cycle.

|

|

9

|

|

10

|

|

12

|

|

1

|

|

2

|

|

3

|

|

4

|

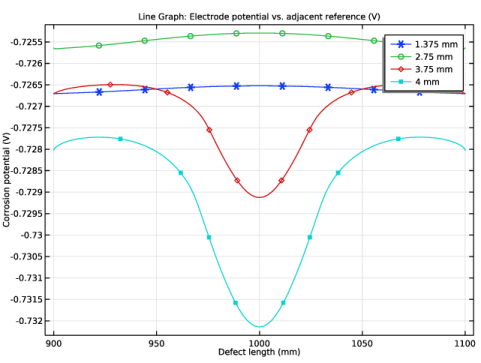

In the associated text field, type Corrosion potential (V).

|

|

1

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Secondary Current Distribution>cd.Evsref - Electrode potential vs. adjacent reference - V.

|

|

3

|

|

1

|

|

2

|

|

3

|

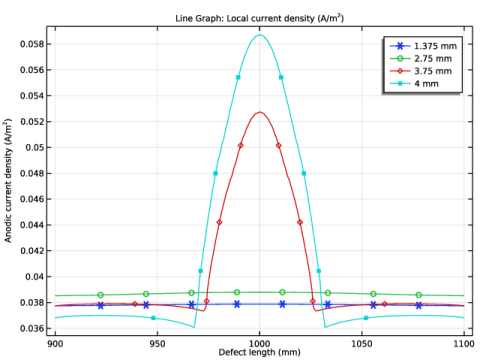

Locate the Plot Settings section. In the y-axis label text field, type Anodic current density (A/m<sup>2</sup>).

|

|

1

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Secondary Current Distribution>Electrode kinetics>cd.iloc_er1 - Local current density - A/m².

|

|

3

|

|

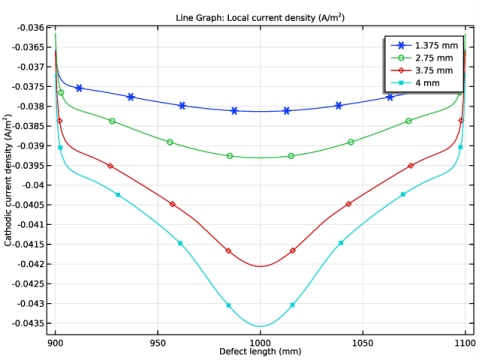

1

|

|

2

|

|

3

|

Locate the Plot Settings section. In the y-axis label text field, type Cathodic current density (A/m<sup>2</sup>).

|

|

1

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Secondary Current Distribution>Electrode kinetics>cd.iloc_er2 - Local current density - A/m².

|

|

3

|