|

|

1

|

|

2

|

In the Select Physics tree, select Electrochemistry>Primary and Secondary Current Distribution>Secondary Current Distribution (cd).

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

Click Browse.

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file ship_hull_geometry.mphbin.

|

|

5

|

Click Import.

|

|

1

|

|

2

|

On the object fin, select Boundaries 9–12 and 15 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file ship_hull_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

9

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

9

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

9

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

9

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

9

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

9

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

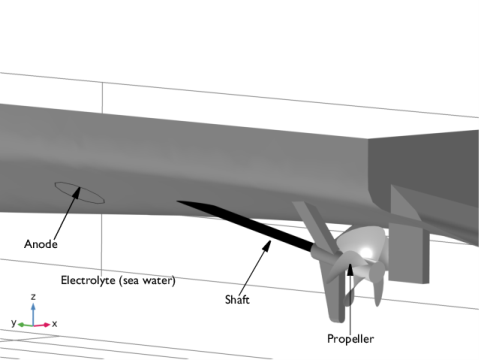

In the Add dialog box, in the Selections to add list, choose Propeller base, Propeller blades, Shaft, Anode, Reference electrode, and Hull surface.

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

9

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Add dialog box, in the Selections to add list, choose Propeller base, Propeller blades, and Shaft.

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

9

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

9

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1)>Materials>Alloy 625 in seawater at 30 C (mat1)>Local current density (lcd) node, then click Interpolation 1 (iloc_exp).

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1)>Materials>NAB in seawater at 30 C (mat2)>Local current density (lcd) node, then click Interpolation 1 (iloc_exp).

|

|

2

|

|

1

|

|

2

|

In the Settings window for Secondary Current Distribution, click to expand the Physics vs. Materials Reference Electrode Potential section.

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Secondary Current Distribution (cd) click Electrolyte 1.

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Electrode Phase Potential Condition section. From the Electrode phase potential condition list, choose Electrode potential.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

4

|

Locate the Geometric Entity Selection section. From the Geometric entity level list, choose Boundary.

|

|

5

|

|

6

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

Select the xy-plane check box.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click the Custom button.

|

|

5

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

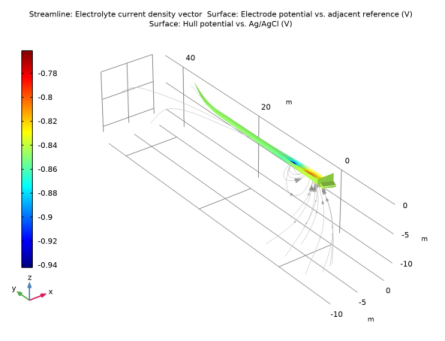

In the Model Builder window, expand the Electrode Potential vs. Adjacent Reference (cd) node, then click Surface 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Electrode Phase Potential Condition section. From the Electrode phase potential condition list, choose Electrode potential.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Electrode Phase Potential Condition section. From the Electrode phase potential condition list, choose Electrode potential.

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, expand the Thin Electrode Surface 1 node, then click Electrode Reaction 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Physics and variables selection tree, select Component 1 (comp1)>Secondary Current Distribution (cd)>Electrode Surface 2.

|

|

5

|

Click

|

|

6

|

In the Physics and variables selection tree, select Component 1 (comp1)>Secondary Current Distribution (cd)>Thin Electrode Surface 1.

|

|

7

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Electrode Potential vs. Adjacent Reference (cd) 1 node, then click Surface 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Secondary Current Distribution>cd.nIl - Normal electrolyte current density - A/m².

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|