|

|

1

|

In the Model Wizard window, Make use of symmetry to model the nail using a 2D axisymmetric geometry.

|

|

2

|

|

3

|

In the Select Physics tree, select Electrochemistry>Primary and Secondary Current Distribution>Secondary Current Distribution (cd).

|

|

4

|

Click Add.

|

|

5

|

Click

|

|

6

|

|

7

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file galvanized_nail_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

Select the object sq1 only.

|

|

3

|

|

4

|

|

5

|

Select the object pol1 only.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Secondary Current Distribution (cd) click Electrolyte 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Electrode Kinetics section. From the Kinetics expression type list, choose Anodic Tafel equation.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Electrode Kinetics section. From the Kinetics expression type list, choose Cathodic Tafel equation.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

8

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

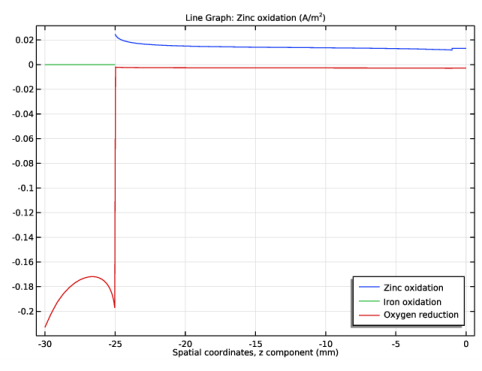

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Secondary Current Distribution>Electrode kinetics>cd.iloc_er1 - Local current density - A/m².

|

|

5

|

|

6

|

In the associated text field, type Zinc oxidation.

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

Select the Description check box.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Secondary Current Distribution>Electrode kinetics>cd.iloc_er2 - Local current density - A/m².

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

Clear the Convection check box.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Transport of Diluted Species (tds) click Transport Properties 1.

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Electrode Surface Coupling 1 node, then click Reaction Coefficients 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Transport of Diluted Species (tds) right-click Electrode Surface Coupling 1 and choose Duplicate.

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Electrode Surface Coupling 2 node, then click Reaction Coefficients 1.

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Secondary Current Distribution (cd)>Electrode Surface 1 click Oxygen reaction.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

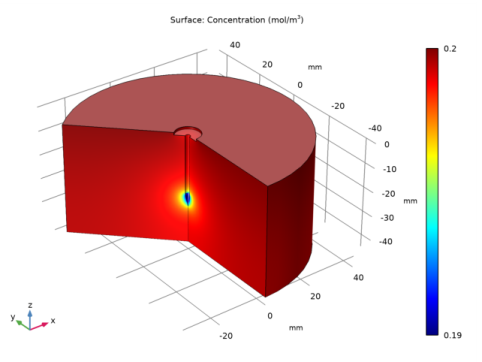

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Transport of Diluted Species>Species c>c - Concentration - mol/m³.

|

|

3

|

|

1

|

|

2

|

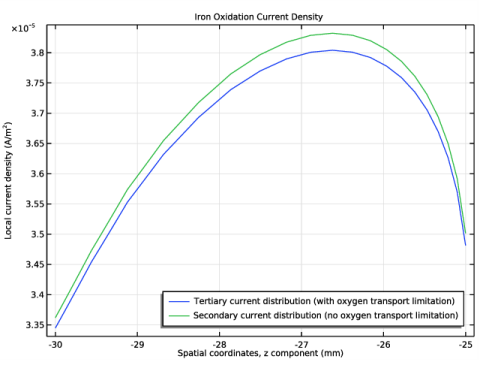

In the Settings window for 1D Plot Group, type Iron Oxidation Current Density in the Label text field.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose cd.iloc_er1 - Local current density - A/m².

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|