|

|

O2

|

H2

|

||||

|

A/m2

|

7.1·10-5

|

7.7·10-7

|

1.1·10-2

|

||

|

1

|

|

2

|

In the Select Physics tree, select Electrochemistry>Tertiary Current Distribution, Nernst-Planck>Tertiary, Supporting Electrolyte (tcd).

|

|

3

|

Click Add.

|

|

4

|

|

5

|

In the Concentrations table, enter the following settings:

|

|

6

|

Click

|

|

7

|

|

8

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file cathodic_protection_in_concrete_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Browse.

|

|

5

|

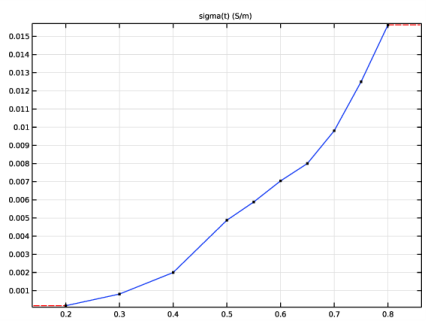

Browse to the model’s Application Libraries folder and double-click the file cathodic_protection_in_concrete_sigma.txt.

|

|

6

|

Click Import.

|

|

7

|

|

8

|

|

9

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Browse.

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file cathodic_protection_in_concrete_D_O2.txt.

|

|

6

|

Click Import.

|

|

7

|

|

8

|

|

9

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Select the object r1 only.

|

|

3

|

|

4

|

|

5

|

Select the object c1 only.

|

|

6

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Tertiary Current Distribution, Nernst-Planck (tcd) click Electrolyte 1.

|

|

2

|

|

3

|

|

4

|

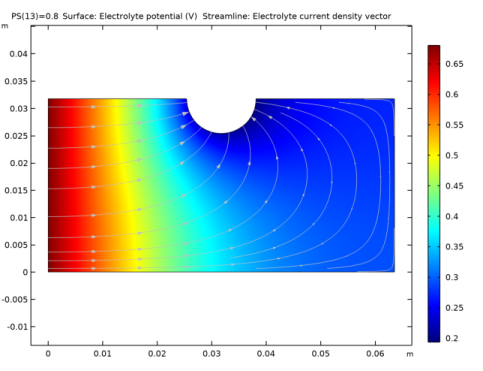

Locate the Electrolyte Current Conduction section. From the σl list, choose User defined. In the associated text field, type sigma(PS).

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

Click OK.

|

|

5

|

|

6

|

|

7

|

Locate the Electrode Kinetics section. From the Kinetics expression type list, choose Thermodynamic equilibrium.

|

|

1

|

|

3

|

In the Settings window for Electrode Surface, locate the Electrode Phase Potential Condition section.

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Click OK.

|

|

5

|

|

6

|

|

7

|

|

8

|

Locate the Equilibrium Potential section. From the Eeq list, choose User defined. In the associated text field, type Eeq_O2.

|

|

9

|

Locate the Electrode Kinetics section. From the Kinetics expression type list, choose Cathodic Tafel equation.

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

Click OK.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

|

1

|

|

2

|

|

1

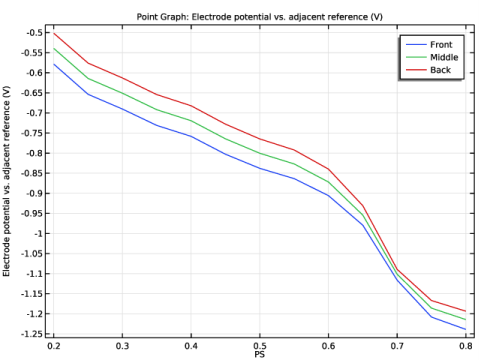

|

|

3

|

In the Settings window for Point Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Tertiary Current Distribution, Nernst-Planck>tcd.Evsref - Electrode potential vs. adjacent reference - V.

|

|

4

|

|

5

|

|

7

|

|

1

|

|

2

|

|

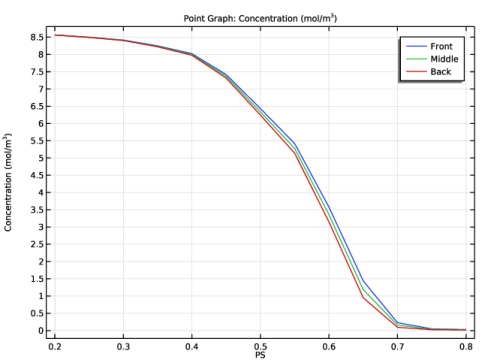

1

|

|

2

|

In the Settings window for Point Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Tertiary Current Distribution, Nernst-Planck>Species c>c - Concentration - mol/m³.

|

|

1

|

|

2

|

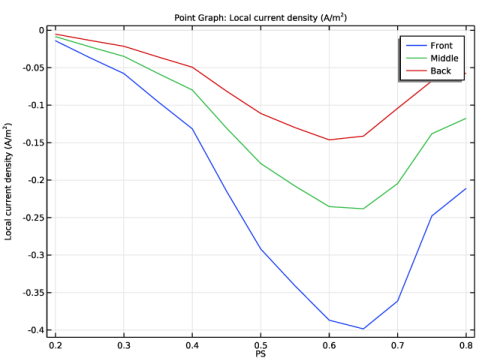

In the Settings window for 1D Plot Group, type Oxygen Reduction Current Density in the Label text field.

|

|

1

|

In the Model Builder window, expand the Oxygen Reduction Current Density node, then click Point Graph 1.

|

|

2

|

In the Settings window for Point Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Tertiary Current Distribution, Nernst-Planck>Electrode kinetics>tcd.iloc_er1 - Local current density - A/m².

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Iron Oxidation Current Density in the Label text field.

|

|

1

|

In the Model Builder window, expand the Iron Oxidation Current Density node, then click Point Graph 1.

|

|

2

|

In the Settings window for Point Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Tertiary Current Distribution, Nernst-Planck>Electrode kinetics>tcd.iloc_er2 - Local current density - A/m².

|

|

3

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Hydrogen Evolution Current Density in the Label text field.

|

|

1

|

In the Model Builder window, expand the Hydrogen Evolution Current Density node, then click Point Graph 1.

|

|

2

|

In the Settings window for Point Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Tertiary Current Distribution, Nernst-Planck>Electrode kinetics>tcd.iloc_er3 - Local current density - A/m².

|

|

3

|