|

|

•

|

|

•

|

|

•

|

|

•

|

|

8.5·10-4

|

5.3·10-4

|

|

|

Diffusivity (m2/s)

|

2.0·10-9

|

2.0·10-9

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file thermal_decomposition_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

Select the object r1 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Click OK.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Click OK.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Click OK.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Click OK.

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Isothermal Flow.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

Find the Initial values of variables solved for subsection. From the Settings list, choose User controlled.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Click OK.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

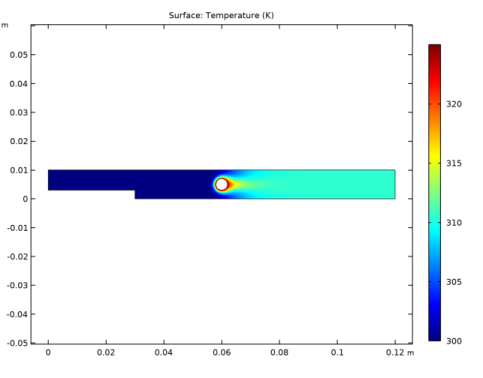

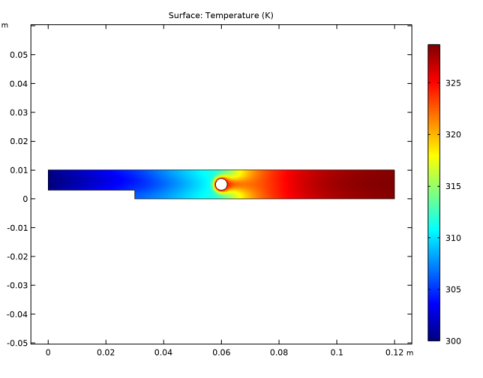

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Heat Transfer in Fluids>Temperature>T - Temperature - K.

|

|

3

|

|

1

|

|

2

|

|

3

|

Click OK.

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check boxes for Isothermal Flow and Nonisothermal Flow.

|

|

5

|

|

6

|

|

7

|

Click to expand the Dependent Variables section. In the table, clear the Solve check boxes for Isothermal Flow and Nonisothermal Flow.

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Apply.

|

|

5

|

|

6

|

|

7

|

|

8

|

Locate the Reaction Thermodynamic Properties section. From the Enthalpy of reaction list, choose User defined.

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click to expand the Species Concentration/Activity section. Select the Constant concentration/activity check box.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Transport of Diluted Species (tds) click Transport Properties 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

Find the Initial values of variables solved for subsection. From the Settings list, choose User controlled.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

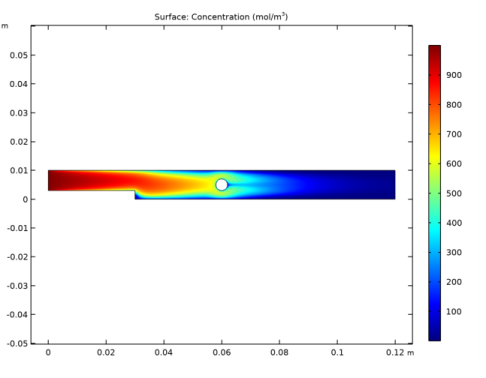

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Transport of Diluted Species>Species cA>cA - Concentration - mol/m³.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

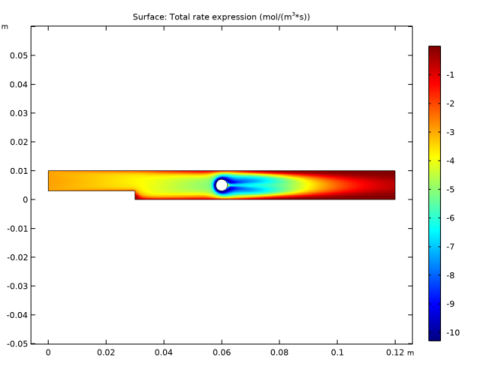

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Transport of Diluted Species>Species cA>tds.R_cA - Total rate expression - mol/(m³·s).

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Click OK.

|