|

|

1

|

|

2

|

Click Next in the window toolbar.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

Click Next in the window toolbar.

|

|

1

|

|

2

|

Click Finish in the window toolbar.

|

|

1

|

|

2

|

|

3

|

Click Next in the window toolbar.

|

|

1

|

|

2

|

|

3

|

Click Finish in the window toolbar.

|

|

1

|

|

2

|

|

3

|

Browse to the model’s Application Libraries folder and double-click the file steam_reformer.mph.

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Add dialog box, in the Selections to add list, choose Bed Inlet, Bed Outlet, Tubes Inlet, and Tubes Outlet.

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file steam_reformer_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Settings window for Transport of Concentrated Species, locate the Transport Mechanisms section.

|

|

2

|

|

3

|

|

4

|

In the Mass fractions table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Settings window for Heat Transfer in Porous Media, click to expand the Dependent Variables section.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Heat Transfer in Fluids, click to expand the Dependent Variables section.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click to expand the Calculate Transport Properties section. Click to collapse the Calculate Transport Properties section.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

In the Model Builder window, under Component 1 (comp1) click Transport of Concentrated Species (tcs).

|

|

2

|

In the Settings window for Transport of Concentrated Species, type Transport of Concentrated Species in Bed in the Label text field.

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Transport of Concentrated Species in Bed (tcs) click Initial Values 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

Locate the Diffusion section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Transport of Concentrated Species in Bed (tcs) click Inflow 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Darcy’s Law in Bed (dl) click Fluid and Matrix Properties 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Matrix Properties section. From the εp list, choose User defined. In the associated text field, type porosity.

|

|

6

|

|

1

|

|

2

|

|

3

|

From the list, choose Pressure.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Heat Transfer in Porous Media, type Heat Transfer in Porous Media in Bed in the Label text field.

|

|

3

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1)>Heat Transfer in Porous Media in Bed (ht)>Porous Medium 1 node, then click Fluid 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Heat Conduction, Porous Matrix section. From the ks list, choose User defined. In the associated text field, type k_pm.

|

|

6

|

Locate the Thermodynamics, Porous Matrix section. From the ρs list, choose User defined. In the associated text field, type dens_pm.

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Heat Conduction, Solid section. From the k list, choose User defined. In the associated text field, type k_foam.

|

|

5

|

Locate the Thermodynamics, Solid section. From the ρ list, choose User defined. In the associated text field, type dens_foam.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Search.

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Laminar Flow, type Laminar Flow in Heating Tubes in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Heat Transfer in Fluids, type Heat Transfer in Heating Tubes in the Label text field.

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Heat Transfer in Heating Tubes (ht2) click Initial Values 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Boundary Layer Properties, locate the Geometric Entity Selection section.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

In the table, clear the Solve for check boxes for Transport of Concentrated Species in Bed (tcs), Heat Transfer in Porous Media in Bed (ht), and Heat Transfer in Heating Tubes (ht2).

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 2 node.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

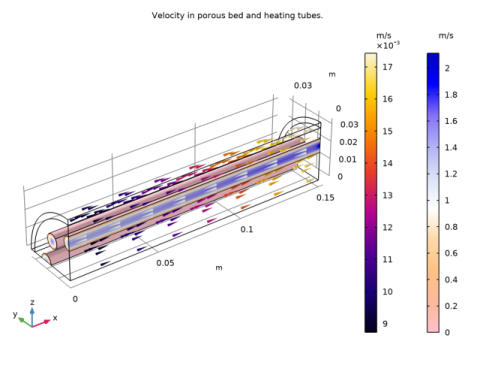

In the Settings window for Volume, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Laminar Flow in Heating Tubes>Velocity and pressure>spf.U - Velocity magnitude - m/s.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Arrow Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Laminar Flow in Heating Tubes>Velocity and pressure>u,v,w - Velocity field.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Mass fraction propane midreactor in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

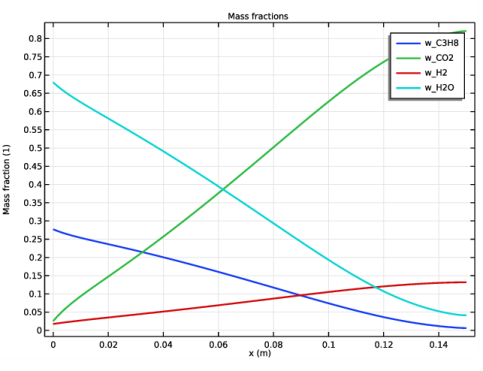

In the Settings window for 1D Plot Group, type Mass fractions along centerline in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

1

|

|

2

|

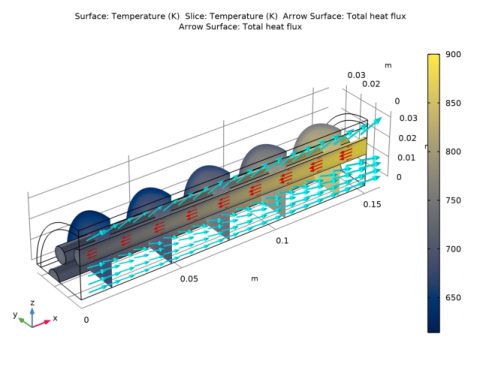

In the Settings window for Arrow Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Heat Transfer in Porous Media in Bed>Domain fluxes>ht.tfluxx,...,ht.tfluxz - Total heat flux.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

In the Settings window for Arrow Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Heat Transfer in Heating Tubes>Domain fluxes>ht2.tfluxx,...,ht2.tfluxz - Total heat flux.

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

9

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Temperature along centerline in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Global Evaluation, type Average temperature in bed outflow in the Label text field.

|

|

3

|

Locate the Expressions section. In the table, enter the following settings:

|

|

4

|

Click

|

|

1

|

|

2

|

In the Settings window for Global Evaluation, type Average temperature in heat tube outflow in the Label text field.

|

|

3

|

Locate the Expressions section. In the table, enter the following settings:

|

|

4

|

Click

|