|

|

•

|

|

•

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file semibatch_polymerization_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file semibatch_polymerization_variables.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Feed Inlet Concentration section. In the Feed inlet concentration table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

Click

|

|

5

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Reaction Engineering>re.sumvf - Sum of volume flows - m³/s.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose Cycle.

|

|

9

|

|

10

|

|

11

|

|

13

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

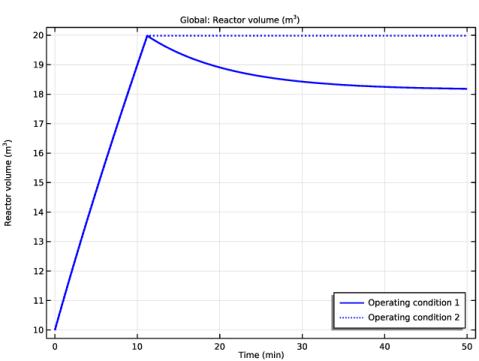

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Reaction Engineering>re.Vr - Reactor volume - m³.

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Cycle.

|

|

7

|

|

8

|

|

9

|

|

11

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>m_mon - Monomer mass - kg.

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Cycle.

|

|

7

|

|

8

|

|

9

|

|

11

|