|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file protein_adsorption_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Apply.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Apply.

|

|

5

|

|

6

|

|

7

|

In the Settings window for Reaction Engineering, click to expand the Equilibrium Species Vector section.

|

|

8

|

|

9

|

Locate the Reactor section. Find the Mass balance subsection. From the Volumetric rate list, choose User defined.

|

|

10

|

|

11

|

|

1

|

|

2

|

In the Settings window for Initial Values, click to expand the Surface Species Initial Values section.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Feed Inlet Concentration section. In the Feed inlet concentration table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

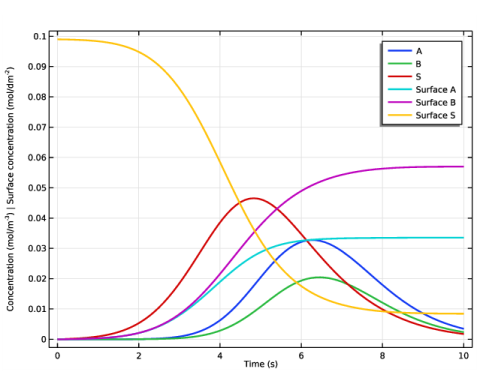

In the associated text field, type Concentration (mol/m<sup>-3</sup>) | Surface concentration (mol/dm<sup>-2</sup>).

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Reaction Engineering>re.c_A - Concentration - mol/m³.

|

|

3

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Reaction Engineering>re.c_B - Concentration - mol/m³.

|

|

4

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Reaction Engineering>re.c_S - Concentration - mol/m³.

|

|

5

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Reaction Engineering>re.csurf_A_surf - Surface concentration - mol/m².

|

|

6

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Reaction Engineering>re.csurf_B_surf - Surface concentration - mol/m².

|

|

7

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Reaction Engineering>re.csurf_S_surf - Surface concentration - mol/m².

|

|

8

|

|

9

|

|

10

|

|

12

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

4

|

|

5

|

In the Settings window for Reaction Engineering, click to expand the Calculate Transport Properties section.

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Physics Interfaces section. Find the Fluid flow subsection. From the list, choose Laminar Flow: New.

|

|

5

|

|

1

|

|

2

|

|

3

|

Browse to the model’s Application Libraries folder and double-click the file protein_adsorption_geom_sequence.mph.

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, expand the Component 2 (comp2)>Transport of Diluted Species (tds) node, then click Inflow 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

1

|

|

2

|

|

3

|

In the table, clear the Solve for check boxes for Reaction Engineering (re), Chemistry 1 (chem), Transport of Diluted Species (tds), and Surface Reactions 1 (sr).

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Physics and Variables Selection section. In the table, clear the Solve for check box for Laminar Flow 1 (spf).

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

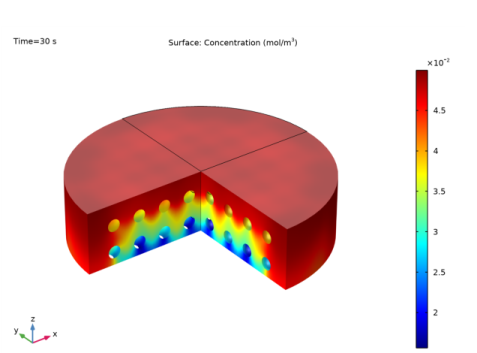

Click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 2 (comp2)>Transport of Diluted Species>Species cB>cB - Concentration - mol/m³.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 2 (comp2)>Surface Reactions 1>Surface species cs_B>cs_B - Surface concentration - mol/m².

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Type list, choose Tube.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

7

|

|

8

|

|

10

|

|

11

|

|

13

|

|

14

|