|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file nonideal_cstr_parameters.txt.

|

|

1

|

|

2

|

In the Settings window for Reaction Engineering, type Reaction Engineering - CSTR 1 in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Reactor section. Find the Mass balance subsection. From the Volumetric rate list, choose Generic.

|

|

7

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Feed Inlet Concentration section. In the Feed inlet concentration table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Feed Inlet Concentration section. In the Feed inlet concentration table, enter the following settings:

|

|

5

|

|

1

|

|

2

|

|

3

|

In the Settings window for Reaction Engineering, type Reaction Engineering - CSTR 2 in the Label text field.

|

|

4

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1)>Reaction Engineering - CSTR 2 (re2) node, then click Initial Values 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Feed Inlet Concentration section. In the Feed inlet concentration table, enter the following settings:

|

|

1

|

|

1

|

|

2

|

|

3

|

In the Parameter table, enter the following settings:

|

|

4

|

Click

|

|

5

|

In the Parameter table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

Click Browse.

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file nonideal_cstr_data.csv.

|

|

5

|

Click Import.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

5

|

In the Physics and variables selection tree, select Component 1 (comp1)>Reaction Engineering - CSTR 1 (re1)>Parameter Estimation 1.

|

|

6

|

Click

|

|

7

|

|

1

|

|

2

|

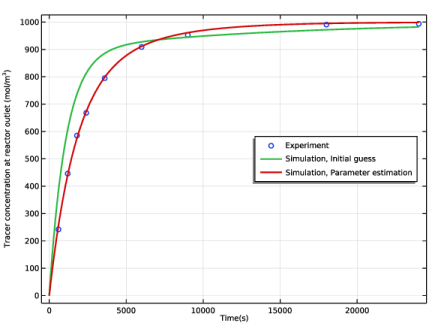

In the Settings window for 1D Plot Group, type Concentration in Real Reactor in the Label text field.

|

|

3

|

|

4

|

|

5

|

In the associated text field, type Time(s).

|

|

6

|

|

7

|

In the associated text field, type Tracer concentration at reactor outlet (mol/m<sup>3</sup>).

|

|

8

|

|

1

|

In the Model Builder window, expand the Concentration in Real Reactor node, then click Experiment 1 Data.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

In the associated text field, type Tracer concentrations (mol/m<sup>3</sup>).

|

|

5

|

|

1

|

|

2

|

In the Settings window for Global, click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Reaction Engineering - CSTR 2>re2.c_T - Concentration - mol/m³.

|

|

3

|

|

4

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 2: Parameter estimation/Solution 2 (sol2).

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Reaction Engineering - CSTR 1>alpha - Global control variable alpha.

|

|

6

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Reaction Engineering - CSTR 1>beta - Global control variable beta.

|

|

7

|

Click

|