|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Stationary Plug Flow.

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file monolith_kinetics_parameters.txt.

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

1

|

|

2

|

Click Next in the window toolbar.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

Click Next in the window toolbar.

|

|

1

|

|

2

|

Click Finish in the window toolbar.

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Reaction Engineering (re) and choose Reaction.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

15

|

|

16

|

|

17

|

|

18

|

|

19

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

|

5

|

Click

|

|

6

|

|

7

|

|

8

|

|

9

|

Click Replace.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Study 1>Solver Configurations click Parametric Solutions 1 - Copy 1 (sol9).

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

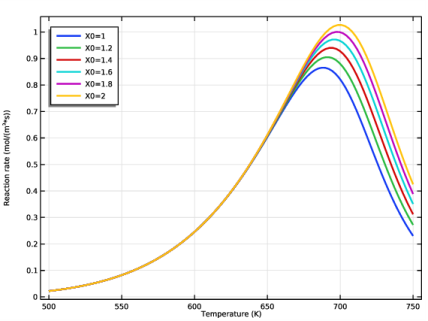

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Reaction Engineering>re.r_1 - Reaction rate - mol/(m³·s).

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>S - Selectivity.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

From the list, choose Include.

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Reaction Engineering (re) click Initial Values 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Study 1>Solver Configurations click Parametric Solutions 1 - Copy 1 (sol22).

|

|

2

|

|

1

|

|

2

|

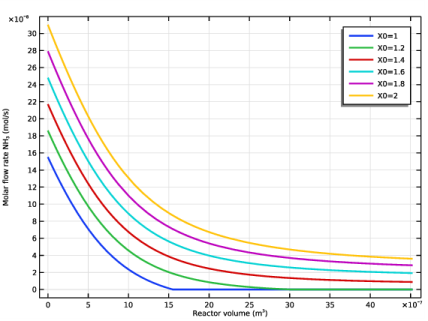

In the Settings window for 1D Plot Group, type Molar flow rate NH3, Nonisothermal in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

In the associated text field, type Molar flow rate NH<sub>3</sub> (mol/s).

|

|

1

|

In the Model Builder window, expand the Molar flow rate NH3, Nonisothermal node, then click Global 1.

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Reaction Engineering>re.F_NH3 - Molar flow rate - mol/s.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

4

|

|

1

|

In the Model Builder window, under Study 1>Solver Configurations click Parametric Solutions 1 - Copy 1 (sol32).

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Definitions>Variables>S - Selectivity.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Reaction Engineering>re.T - Temperature - K.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|