|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file dna_degradation_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

In the Parameter table, enter the following settings:

|

|

4

|

Click

|

|

5

|

In the Parameter table, enter the following settings:

|

|

6

|

Click

|

|

7

|

In the Parameter table, enter the following settings:

|

|

8

|

Click

|

|

9

|

In the Parameter table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

Click Browse.

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file dna_degradation_experiment1.csv.

|

|

5

|

Click Import.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

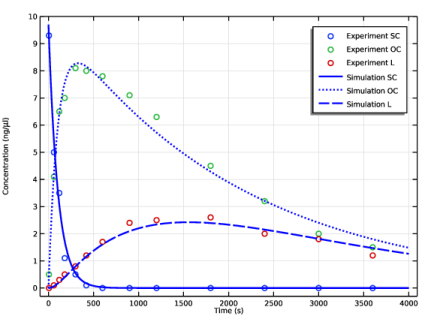

In the associated text field, type Time (s).

|

|

6

|

|

7

|

In the associated text field, type Concentration (ng/\mu l).

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Reaction Engineering>re.c_SC - Concentration - mol/m³.

|

|

4

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Reaction Engineering>re.c_OC - Concentration - mol/m³.

|

|

5

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Reaction Engineering>re.c_L - Concentration - mol/m³.

|

|

6

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose Cycle.

|

|

7

|

|

8

|

|

9

|

|

11

|

|

12

|

|

13

|