|

|

1

|

|

2

|

In the Select Physics tree, select Fluid Flow>High Mach Number Flow>Turbulent Flow>High Mach Number Flow, Spalart-Allmaras (hmnf).

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Stationary with Initialization.

|

|

6

|

Click

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

Locate the Parameters section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Functions subsection. In the table, enter the following settings:

|

|

5

|

Click Browse.

|

|

6

|

Browse to the model’s Application Libraries folder and double-click the file sajben_diffuser_upper_wall.txt.

|

|

7

|

Click Import.

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Functions subsection. In the table, enter the following settings:

|

|

5

|

Click Browse.

|

|

6

|

Browse to the model’s Application Libraries folder and double-click the file sajben_diffuser_ptop_weak.txt.

|

|

7

|

Click Import.

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Functions subsection. In the table, enter the following settings:

|

|

5

|

Click Browse.

|

|

6

|

Browse to the model’s Application Libraries folder and double-click the file sajben_diffuser_ptop_strong.txt.

|

|

7

|

Click Import.

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Functions subsection. In the table, enter the following settings:

|

|

5

|

Click Browse.

|

|

6

|

Browse to the model’s Application Libraries folder and double-click the file sajben_diffuser_u-xh4611.txt.

|

|

7

|

Click Import.

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Functions subsection. In the table, enter the following settings:

|

|

5

|

Click Browse.

|

|

6

|

Browse to the model’s Application Libraries folder and double-click the file sajben_diffuser_u-xh6340.txt.

|

|

7

|

Click Import.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select both objects.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

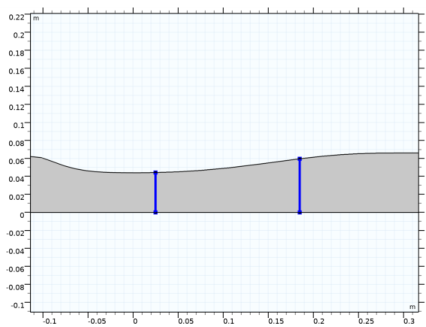

Select the object csol1 only.

|

|

3

|

|

4

|

|

5

|

Select the object r1 only.

|

|

6

|

|

1

|

|

2

|

On the object fin, select Boundaries 3 and 5 only.

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>High Mach Number Flow, Spalart-Allmaras (hmnf) click Fluid 1.

|

|

2

|

|

3

|

|

4

|

Locate the Thermodynamics section. From the Rs list, choose User defined. In the associated text field, type Rs.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

Specify the u vector as

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Show More Options dialog box, in the tree, select the check box for the node Physics>Advanced Physics Options.

|

|

3

|

Click OK.

|

|

4

|

|

5

|

In the Settings window for High Mach Number Flow, Spalart-Allmaras, click to expand the Advanced Settings section.

|

|

6

|

|

7

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Stationary with Initialization.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Click

|

|

1

|

|

2

|

In the Settings window for Wall Distance Initialization, click to expand the Values of Dependent Variables section.

|

|

3

|

Find the Values of variables not solved for subsection. From the Settings list, choose User controlled.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

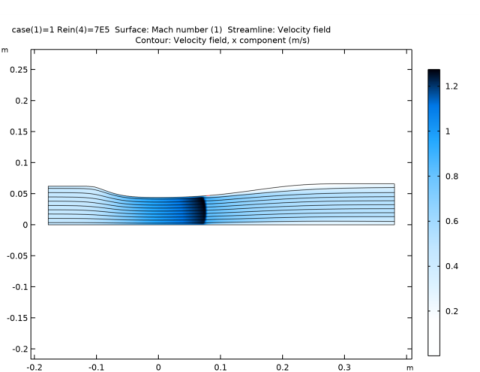

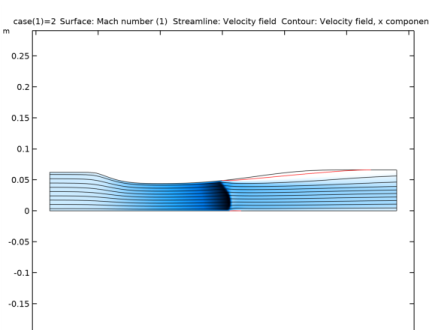

In the Settings window for Streamline, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>High Mach Number Flow, Spalart-Allmaras (Fluid Flow)>Velocity and pressure>u,v - Velocity field.

|

|

4

|

|

1

|

|

2

|

In the Settings window for Contour, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>High Mach Number Flow, Spalart-Allmaras (Fluid Flow)>Velocity and pressure>Velocity field - m/s>u - Velocity field, x component.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

Click Replace Expression in the upper-right corner of the x-Axis Data section. From the menu, choose Component 1 (comp1)>Geometry>Coordinate>x - x-coordinate.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose None.

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>High Mach Number Flow, Spalart-Allmaras (Fluid Flow)>Velocity and pressure>Velocity field - m/s>u - Velocity field, x component.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose None.

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

In the associated text field, type u (m/s).

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

15

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|