|

|

1

|

|

2

|

In the Select Physics tree, select Fluid Flow>Single-Phase Flow>Turbulent Flow>Turbulent Flow, k-ω (spf).

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Select the object c1 only.

|

|

4

|

|

5

|

|

6

|

Select the object sq1 only.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

Click the Angles button.

|

|

4

|

|

5

|

Select the object wp1 only.

|

|

6

|

|

7

|

Locate the Revolution Axis section. Find the Point on the revolution axis subsection. In the xw text field, type Rc.

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1)>Geometry 1>Work Plane 2 (wp2)>Plane Geometry node, then click Circle 1 (c1).

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Turbulent Flow, k-ω (spf) and choose Inlet.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Boundary Layers 1 node, then click Boundary Layer Properties 1.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Streamline Positioning section. From the Positioning list, choose On selected boundaries.

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

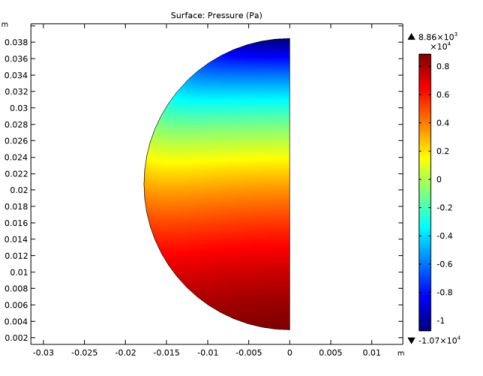

In the Rename 2D Plot Group dialog box, type Cut Plane Pressure Distribution in the New label text field.

|

|

3

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|

Click

|

|

6

|

|

7

|

Click

|