|

|

k-ε

|

|

1

|

|

2

|

In the Select Physics tree, select Fluid Flow>Single-Phase Flow>Turbulent Flow>Turbulent Flow, k-ε (spf).

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

Click Browse.

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file ahmed_body.mphbin.

|

|

5

|

Click Import.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

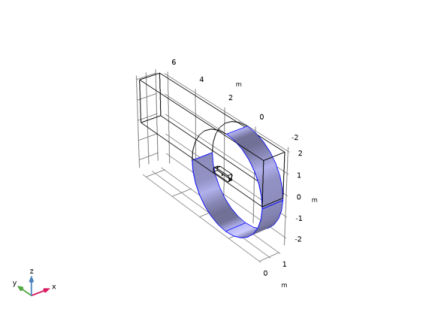

Select the object blk1 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

On the object cyl1, select Boundaries 1, 3, and 4 only.

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select both objects.

|

|

3

|

|

1

|

|

2

|

On the object uni1, select Boundaries 10 and 16 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object del2, select Boundary 22 only.

|

|

5

|

Click to expand the Local Coordinate System section. From the Origin list, choose Vertex projection.

|

|

6

|

|

7

|

On the object del2, select Point 27 only.

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 right-click Work Plane 1 (wp1) and choose Extrude.

|

|

2

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

On the object ige1, select Domain 2 only.

|

|

1

|

|

2

|

|

3

|

On the object mcd1, select Boundary 12 only.

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Browse.

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file ahmed_body_kin.txt.

|

|

6

|

Click Import.

|

|

7

|

Find the Functions subsection. In the table, enter the following settings:

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

In the tree, select Built-in>Air.

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Turbulent Flow, k-ε (spf) and choose Wall.

|

|

2

|

|

3

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

In the Show More Options dialog box, in the tree, select the check box for the node Physics>Advanced Physics Options.

|

|

11

|

Click OK.

|

|

12

|

|

13

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Mesh 1 and choose Edit Physics-Induced Sequence.

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

8

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Boundary Layers 1 node, then click Boundary Layer Properties 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

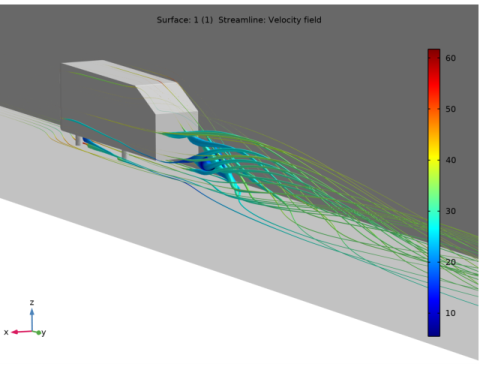

In the x text field, type range(0.01,0.03,0.16) range(0.01,0.03,0.16) range(0.01,0.03,0.16) range(0.01,0.03,0.16) range(0.01,0.03,0.16).

|

|

6

|

|

7

|

In the z text field, type 0.02*1^range(1,6) 0.08*1^range(1,6) 0.14*1^range(1,6) 0.2*1^range(1,6) 0.26*1^range(1,6).

|

|

8

|

Locate the Coloring and Style section. Find the Line style subsection. From the Type list, choose Tube.

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

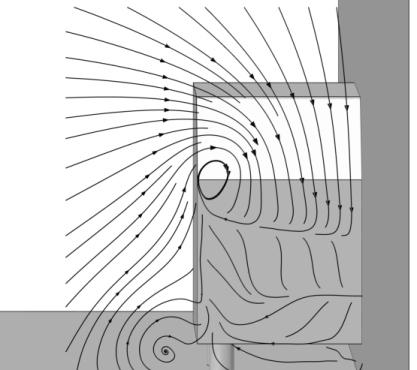

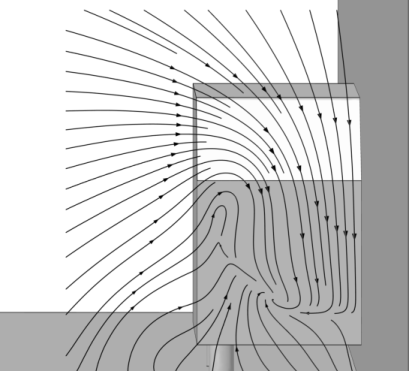

In the Settings window for 3D Plot Group, type Streamline: Velocity in xz-plane, 80†mm in the Label text field.

|

|

3

|

Click to expand the Title section.

|

|

1

|

In the Streamline: Velocity in xz-plane, 80†mm toolbar, click

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Coloring and Style section. Find the Line style subsection. From the Type list, choose Tube.

|

|

7

|

|

8

|

|

9

|

|

10

|

|

12

|

|

13

|

|

14

|

|

15

|

|

16

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, right-click Streamline: Velocity in xz-plane, 80 mm and choose Surface.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

In the Settings window for 3D Plot Group, type Streamline: Velocity in xz-plane, 200†mm in the Label text field.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|